Descrizione

Introduzione ai PCB con anima in metallo

Il Metal Core PCB rappresenta una svolta nella moderna tecnologia elettronica di dissipazione del calore. Come professionista Produttore di PCBSiamo consapevoli che un'efficace gestione termica è diventata un fattore critico nel determinare le prestazioni e l'affidabilità dei prodotti nei dispositivi elettronici ad alta densità di potenza di oggi’.Rispetto ai tradizionali circuiti stampati FR4, i circuiti stampati con anima in metallo offrono prestazioni di dissipazione del calore senza pari grazie alla loro esclusiva struttura a substrato metallico, che li rende particolarmente adatti ad applicazioni ad alto carico termico come l'illuminazione a LED, l'elettronica automobilistica, la conversione di potenza e il controllo industriale.

Il nostro processo di produzione di MCPCB integra una scienza dei materiali avanzata e una tecnologia di lavorazione di precisione per garantire che ogni scheda di circuito mantenga prestazioni stabili in condizioni operative difficili.Grazie all'utilizzo di substrati metallici ad alta conduttività termica e di design ottimizzati degli strati dielettrici, gli MCPCB che produciamo sono in grado di condurre e dissipare rapidamente il calore generato dai componenti, riducendo in modo significativo le temperature di esercizio e prolungando la durata dei componenti elettronici.

I principali vantaggi dei PCB con anima in metallo

Prestazioni termiche eccezionali

Tra i numerosi vantaggi dei PCB con anima in metallo, spicca l'eccezionale capacità di dissipazione del calore. I dati dei nostri test dimostrano che gli MCPCB a base di alluminio migliorano l'efficienza di dissipazione del calore di 8-10 volte rispetto ai PCB FR4 tradizionali, mentre gli MCPCB a base di rame possono ottenere un miglioramento di oltre 15 volte. Questo notevole miglioramento termico deriva dall'elevata conduttività termica dei nuclei metallici: l'alluminio ha una conduttività termica di 237W/mK, mentre il rame raggiunge ben 393W/mK.

I nostri strati dielettrici, appositamente progettati, non solo forniscono il necessario isolamento elettrico, ma presentano anche un'eccellente conduttività termica, garantendo un efficiente trasferimento di calore dagli strati del circuito al substrato metallico.Questo design consente agli MCPCB di gestire densità di potenza molto più elevate rispetto ai PCB convenzionali, pur mantenendo temperature di esercizio inferiori.Questa caratteristica è particolarmente importante per i componenti ad alto calore come i LED di potenza e i moduli IGBT.

Maggiore affidabilità del sistema

Lo stress termico è una delle principali cause di guasto dei dispositivi elettronici. I nostri circuiti stampati con anima metallica controllano efficacemente le temperature di esercizio, riducendo in modo significativo l'espansione e la contrazione del materiale causate dai cicli termici, minimizzando così i rischi di crepe nei giunti di saldatura, delaminazione e guasti dei componenti. Dati applicativi reali indicano che i dispositivi LED che utilizzano i nostri MCPCB possono prolungare la durata media del 30-50%, mentre i moduli di potenza vedono ridotti i tassi di guasto di oltre il 40%.

Il substrato metallico offre inoltre un'eccellente resistenza meccanica e stabilità dimensionale, impedendo la deformazione del PCB in ambienti ad alta temperatura. Questo lo rende particolarmente adatto ad applicazioni con forti vibrazioni e fluttuazioni di temperatura, come i vani motore delle automobili e gli azionamenti dei motori industriali. I feedback dei clienti dimostrano che, in condizioni operative identiche, gli MCPCB hanno un MTBF (Mean Time Between Failures) 2-3 volte superiore rispetto ai PCB tradizionali.

Progettazione del sistema semplificata

Scegliere i nostri circuiti stampati con anima in metallo significa semplificare la progettazione termica dell'intero sistema elettronico’. Componenti aggiuntivi come dissipatori di calore e pad termici, che devono essere considerati nei progetti tradizionali, possono essere sostanzialmente ridotti o addirittura eliminati con le soluzioni MCPCB. Questo non solo riduce i costi della distinta base, ma consente anche di risparmiare spazio prezioso per l'installazione, permettendo di realizzare prodotti più compatti.

Il nostro team di ingegneri fornisce un supporto professionale alla progettazione per ottimizzare il layout dei componenti e sfruttare appieno le caratteristiche termiche degli MCPCB’.Grazie alla progettazione razionale di vias termici e aree di rame, otteniamo una distribuzione ottimale del calore, preveniamo il surriscaldamento localizzato e manteniamo le prestazioni elettriche della scheda.Questa soluzione integrata è particolarmente adatta ai dispositivi portatili con limiti di spazio e alle applicazioni di imballaggio ad alta densità.

Processo di produzione professionale di PCB con anima in metallo

Selezione e lavorazione di precisione dei materiali

Con 17 anni di esperienza come produttore di PCB, abbiamo stabilito standard rigorosi per la selezione dei materiali dei PCB con anima in metallo. Offriamo diverse opzioni di substrato metallico, tra cui:

-

Substrati di alluminio standard (spessore da 1,0 mm a 3,0 mm)

-

Substrati in alluminio ad alta conducibilità termica (2,0W/mK)

-

Substrati di rame (spessore da 1,0 mm a 5,0 mm)

-

Substrati compositi rame-alluminio (equilibrio tra costi e prestazioni)

I nostri strati dielettrici utilizzano materiali polimerici speciali riempiti di ceramica con un'eccellente conduttività termica (1,5W/mK) e un'elevata rigidità dielettrica (3kV). Controllando con precisione lo spessore dello strato dielettrico (in genere 75-150μm), otteniamo un equilibrio ottimale tra prestazioni di isolamento e conduzione del calore.

Tecnologia di lavorazione avanzata

La produzione di PCB con anima in metallo deve affrontare sfide che non si incontrano con i PCB tradizionali, in particolare nella lavorazione del substrato metallico. Abbiamo investito in attrezzature specializzate per la lavorazione dei substrati metallici, tra cui:

-

Fresatrici CNC ad alta precisione (contornatura di substrati metallici)

-

Sistemi di foratura laser (lavorazione di microvia)

-

Linee di rettifica in ceramica (trattamento superficiale)

-

Linee di produzione VCP (Vertical Continuous Plating)

Il nostro team di ingegneri di processo ha sviluppato flussi di lavoro specializzati per la lavorazione di PCB con anima in metallo che risolvono i problemi di deformazione causati dalle discrepanze CTE tra i substrati metallici e i materiali FR4, garantendo un'elevata planarità della scheda (<0,5% di deformazione). Per i substrati di rame, impieghiamo speciali processi di trattamento superficiale per prevenire l'ossidazione e garantire una buona saldabilità.

Controllo di qualità rigoroso

La qualità è l'ancora di salvezza dei nostri prodotti e implementiamo un rigoroso controllo di qualità per ogni PCB con anima in metallo:

-

Ispezione delle materie prime (planarità del substrato metallico, prestazioni termiche dello strato dielettrico)

-

Controllo qualità in-process (larghezza/spazio della traccia, precisione della posizione del foro)

-

Test finale completo che comprende:

-

Test di resistenza termica

-

Test di resistenza alla tensione di isolamento (AC 3kV/1min senza guasti)

-

Test di ciclismo termico (-40°C~+150°C, 100 cicli)

-

Analisi della sezione trasversale (spessore del foro passante placcato, integrità dello strato dielettrico)

Disponiamo di un laboratorio di prova ben attrezzato con strumenti avanzati come termocamere e analizzatori di rete per garantire che i prodotti spediti soddisfino i requisiti dei clienti in termini di prestazioni elettriche, termiche e meccaniche. Per le applicazioni ad alta affidabilità (ad esempio, l'elettronica automobilistica), possiamo fornire ulteriori rapporti di verifica dell'affidabilità.

Applicazioni tipiche dei PCB con anima in metallo

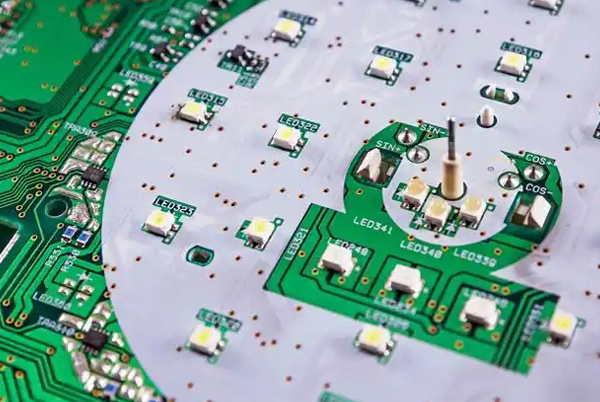

Soluzioni di illuminazione a LED

L'industria dei LED è uno dei campi di applicazione più importanti per i nostri PCB ad anima metallica. L'efficienza luminosa dei LED ad alta luminosità è strettamente correlata alla temperatura di giunzione: i nostri MCPCB a base di alluminio possono ridurre le temperature di giunzione dei LED di 20-30°C, migliorando significativamente l'efficienza luminosa (circa il 10-15%) e prolungando la vita utile. Forniamo soluzioni professionali per varie applicazioni LED:

-

Illuminazione stradale (array di LED ad alta potenza)

-

Illuminazione automobilistica (fari, luci diurne)

-

Illuminazione commerciale (faretti, lampade a pannello)

-

Illuminazione speciale (LED UV, luci per la crescita delle piante)

Per i diversi gradi di potenza dei LED, abbiamo sviluppato soluzioni MCPCB serializzate, da strutture semplici per LED singoli da 1W a progetti ad alta densità per pacchetti COB da oltre 100W, tutti con gestione termica ottimizzata. I casi dei clienti dimostrano che i dispositivi LED che utilizzano i nostri MCPCB presentano un deprezzamento dei lumen inferiore al 3% (5000 ore) a una temperatura ambiente di 45°C, superando di gran lunga gli standard del settore.

Sistemi elettronici per autoveicoli

I severi requisiti di affidabilità dell'elettronica automobilistica rendono i PCB metal core una scelta ideale. Le nostre soluzioni MCPCB per il settore automobilistico includono:

-

Controllori di motori per veicoli a nuova energia

-

Caricabatterie di bordo (OBC)

-

Moduli di conversione CC-CC

-

Driver per illuminazione automotive a LED

-

Sistemi di gestione delle batterie (BMS)

Queste applicazioni presentano caratteristiche comuni di alta densità di potenza e ambienti operativi difficili (alte temperature, vibrazioni). Utilizziamo materiali e processi di substrato speciali per garantire che i nostri MCPCB soddisfino gli standard AEC-Q200 dell'elettronica automobilistica. Ad esempio, i nostri MCPCB a base di rame mantengono prestazioni stabili a temperature elevate di 150°C e soddisfano i requisiti dei cicli termici di tipo automobilistico (-40°C~+150°C).

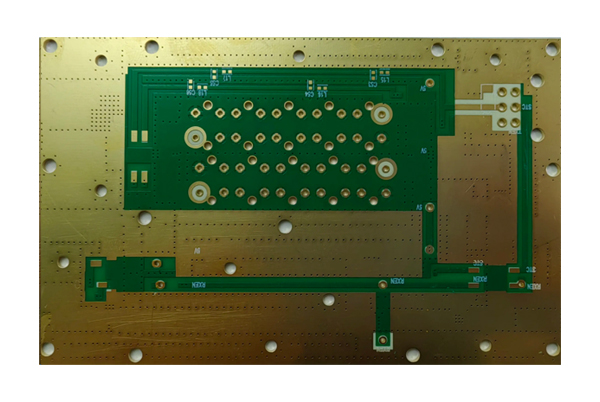

Potenza industriale ed elettronica di potenza

Nei settori dell'elettronica di potenza, come gli alimentatori industriali, i convertitori di frequenza e i servoazionamenti, i nostri circuiti stampati con anima metallica aiutano i clienti a risolvere i problemi di raffreddamento dei dispositivi di potenza come gli IGBT e i MOSFET. Le applicazioni tipiche includono:

-

Alimentatori switching ad alta potenza (1kW)

-

Inverter fotovoltaici

-

Convertitori di frequenza industriali

-

Alimentatori per saldatrici

-

Gruppi di continuità (UPS)

Per applicazioni con diversi livelli di corrente, forniamo soluzioni di circuiti stampati con anima in metallo che vanno dal singolo strato al multistrato (2-6 strati). Per le applicazioni a corrente estremamente elevata, abbiamo sviluppato substrati metallici a rame spesso (spessore dello strato esterno di rame fino a 400μm), riducendo in modo significativo la resistenza di conduzione e la resistenza termica. I dati delle applicazioni reali dimostrano che i nostri MCPCB possono ridurre l'aumento di temperatura nei moduli di potenza di 15-20°C, migliorando notevolmente l'efficienza e l'affidabilità del sistema.

Servizi personalizzati e assistenza tecnica

Supporto alla progettazione ingegneristica

Siamo consapevoli che ogni applicazione ha requisiti unici, quindi offriamo servizi completi di supporto alla progettazione:

-

Analisi di simulazione termica: Utilizzo di un software professionale per prevedere la distribuzione della temperatura dei PCB

-

Raccomandazioni per l'ottimizzazione strutturale:Spessore del substrato metallico, selezione dei parametri dello strato dielettrico

-

Soluzioni di ottimizzazione dei costi:Trovare il miglior equilibrio tra prestazioni e costi

-

Revisione della progettazione per la producibilità (DFM):Garantire che i progetti siano adatti alla produzione di massa

Il nostro team di ingegneri ha una vasta esperienza nella progettazione di MCPCB e ha aiutato numerosi clienti a risolvere problemi di gestione termica.Ad esempio, abbiamo sviluppato un PCB con anima metallica di forma irregolare per un cliente di dispositivi medici che ha ottenuto un raffreddamento efficace per i chip ad alto flusso di calore in uno spazio limitato, riducendo la temperatura operativa del dispositivo da 95°C a 65°C.

Servizi di prototipazione rapida

Per i clienti in fase di R&D, offriamo servizi di produzione rapida di campioni di MCPCB:

-

Campioni standard di PCB in alluminio: 5-7 giorni di consegna

-

Campioni di PCB in rame:Consegna in 7-10 giorni

-

Campioni di strutture complesse:Tempi di consegna determinati in base ai requisiti specifici

Disponiamo di linee di produzione dedicate per piccoli lotti, in grado di rispondere rapidamente alle esigenze di campionatura dei clienti.Forniamo inoltre rapporti di prova sui campioni per aiutare i clienti a verificare l'efficacia del progetto. Molti clienti riferiscono che i nostri servizi di prototipazione rapida abbreviano notevolmente i cicli di sviluppo dei prodotti.

Capacità produttive flessibili

In qualità di produttore professionale con una base produttiva di 20.000 metri quadrati, offriamo servizi di produzione altamente flessibili:

-

Produzione di massa: Capacità mensile fino a 50.000 metri quadrati

-

Piccoli lotti multivariati:Adatto a clienti con prodotti diversi

-

Processi speciali:Come l'ispessimento localizzato dei substrati metallici, il trattamento selettivo di dissipazione del calore.

-

Servizi one-stop:Soluzioni per l'intero processo, dal PCB all'assemblaggio

Il nostro sistema di gestione della produzione consente la piena tracciabilità, garantendo la coerenza della qualità tra i lotti di produzione.Per i clienti che collaborano da lungo tempo, forniamo anche configurazioni di linee di produzione dedicate e soluzioni di gestione delle scorte per garantire forniture tempestive.

Perché scegliere i nostri servizi di PCB con anima in metallo

Capacità professionali leader del settore

Dalla sua fondazione nel 2008, Topfast è cresciuta fino a diventare un fornitore leader nel settore dei circuiti stampati con anima in metallo. Le nostre competenze principali includono:

-

Team tecnico professionale:100+ ingegneri esperti

-

Attrezzature avanzate:Attrezzature specializzate come macchine per la foratura laser e linee di produzione VCP

-

Processi maturi:17 anni di esperienza accumulata nella produzione di MCPCB

-

Sistemi di qualità completi:Certificazioni ISO9001 e IATF16949

Non forniamo solo prodotti, ma anche soluzioni.Molti clienti hanno riscontrato miglioramenti significativi nelle prestazioni termiche dei loro prodotti e nella loro competitività sul mercato dopo aver collaborato con noi.

Storie di successo dei clienti

I nostri PCB con anima in metallo sono stati applicati con successo in numerosi progetti di riferimento del settore:

-

Un progetto di lampione a LED di marca internazionale: L'utilizzo dei nostri PCB in alluminio ad alta conduttività termica ha aumentato la durata del dispositivo da 30.000 a 50.000 ore.

-

Un nuovo progetto OBC per veicoli energetici:Gli MCPCB a base di rame hanno aiutato il cliente ad aumentare la densità di potenza del 30%.

-

Un progetto di convertitore di frequenza industriale:I nostri PCB multistrato con anima metallica hanno risolto i problemi di raffreddamento dei moduli IGBT ad alta potenza

Queste storie di successo dimostrano l'affidabilità e la praticità delle nostre soluzioni tecniche.Siamo lieti di condividere queste esperienze per aiutare i nuovi clienti a realizzare rapidamente gli aggiornamenti dei prodotti.

Proposta di valore competitivo

Ci impegniamo a fornire ai clienti le migliori soluzioni MCPCB in termini di costi e prestazioni:

-

Ottimizzazione dei materiali: Aiutare i clienti a selezionare i materiali del substrato più adatti, evitando un'eccessiva ingegnerizzazione.

-

Innovazione di processo:Riduzione dei costi di produzione attraverso l'ottimizzazione dei processi

-

Economie di scala:Ottenere prezzi competitivi delle materie prime grazie all'acquisto di grandi quantità

-

Servizi localizzati:Risposta rapida, riduzione dei costi di comunicazione

Rispetto ai colleghi, siamo in grado di offrire prodotti più competitivi in termini di prezzo, pur garantendo la qualità.Molti clienti riferiscono che le nostre soluzioni MCPCB li aiutano a ridurre i costi totali del sistema, migliorando al contempo l'affidabilità del prodotto.

Perché scegliere Topfast?

Come soluzione chiave per la gestione termica dei moderni dispositivi elettronici, i PCB metal core stanno dimostrando il loro valore insostituibile in campi sempre più diversi.Che si tratti di illuminazione a LED ad alta luminosità, di elettronica automobilistica a nuova energia o di apparecchiature industriali di potenza, gli MCPCB offrono prestazioni termiche eccezionali, maggiore affidabilità del sistema e architetture di progettazione semplificate.

Con 17 anni di esperienza professionale come produttore di PCB, Topfast si impegna a fornire ai clienti soluzioni PCB metal core della massima qualità.Dalla selezione dei materiali e dalla progettazione dei processi alla produzione di massa, ci atteniamo agli standard più elevati per garantire che ogni MCPCB soddisfi i requisiti applicativi più esigenti. Il nostro team di ingegneri è pronto a fornire consulenza tecnica e supporto alla progettazione per aiutarvi a risolvere i problemi di gestione termica più impegnativi.

Se siete alla ricerca di un partner affidabile per i circuiti stampati con anima in metallo o se avete domande sull'idoneità della vostra applicazione attuale per gli MCPCB, non esitate a contattare il nostro team di professionisti.Vi forniremo soluzioni ottimizzate in base alle vostre esigenze specifiche per aiutare i vostri prodotti a distinguersi dalla concorrenza.

Richiedi un preventivo e ordinare PCB personalizzati con anima in metallo