Description

The metal-reinforced rigid-flex composite panel is an innovative structural board that combines high strength with flexible deformation capabilities, making it widely applicable in industries such as aerospace, automotive manufacturing, construction, and electronic devices. This product integrates high-rigidity metal reinforcement ribs (e.g., aluminum alloy, titanium alloy, or high-strength steel) as the core support layer with high-toughness polymer substrates (e.g., engineering plastics or composite materials) through advanced manufacturing processes, achieving an optimal balance between rigidity and flexibility.

Key Features

- High Strength & Lightweight: Metal reinforcement significantly enhances bending and compression resistance while maintaining a lightweight design.

- Dynamic Adaptability: The flexible substrate allows controlled bending deformation, making it suitable for irregular structures or shock-absorbing applications.

- Enhanced Durability: Corrosion-resistant metal layers and weatherproof polymers ensure long-term stability.

- Multifunctional Integration: Can incorporate conductive, thermal-insulating, or electromagnetic shielding layers for diverse requirements.

Product Parameter Properties

| Item |

Rigid-Flexible PCB |

Flexible PCB |

| Max Layer |

36L |

8L |

| Inner Layer Min Trace/Space |

3/3mil |

3/3mil |

| Outer Layer Min Trace/Space |

3.5/4mil |

3.5/4mil |

| Inner Layer Max Copper |

6oz |

2oz |

| Outer Layer Max Copper |

3oz |

2oz |

| Min Mechanical Drilling |

0.15mm |

0.1mm |

| Mini Laser Drilling |

0.1mm |

0.1mm |

| Aspect Ratio(Mechanical Drilling) |

12:1 |

10:1 |

| Aspect Ratio(Laser Drilling) |

1:1 |

/ |

| Press Fit Hole Ttolerance |

±0.05mm |

±0.05mm |

| PTH Tolerance |

±0.075mm |

±0.075mm |

| NPTH Tolerance |

±0.05mm |

±0.05mm |

| Countersink Tolerance |

±0.15mm |

±0.15mm |

| Board Thickness |

0.4-3mm |

0.1-0.5mm |

| Board Thickness Tolerance(<1.0mm) |

±0.1mm |

±0.05mm |

| Board Thickness Tolerance(≥1.0mm) |

±10% |

/ |

| Impedance Tolerance |

Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

| Differential:±5Ω(≤50Ω),±10%(>50Ω) |

Differential:±5Ω(≤50Ω),±10%(>50Ω) |

| Min Board Size |

10*10mm |

5*10mm |

| Max Board Size |

22.5*30inch |

9*14inch |

| Contour Tolerance |

±0.1mm |

±0.05mm |

| Min BGA |

7mil |

7mil |

| Min SMT |

7*10mil |

7*10mil |

| Surface Treatment |

ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask |

Green,Black,Blue,Red,Matt Green |

Green Solder Mask/Black PI/Yellow PI |

| Min Solder Mask Clearance |

1.5mil |

3mil |

| Min Solder Mask Dam |

3mil |

8mil |

| Legend |

White,Black,Red,Yellow |

White,Black,Red,Yellow |

| Min Legend Width/Height |

4/23mil |

4/23mil |

| Strain Fillet Width |

1.5±0.5mm |

1.5+0.5mil |

| Bow & Twist |

0.05% |

/ |

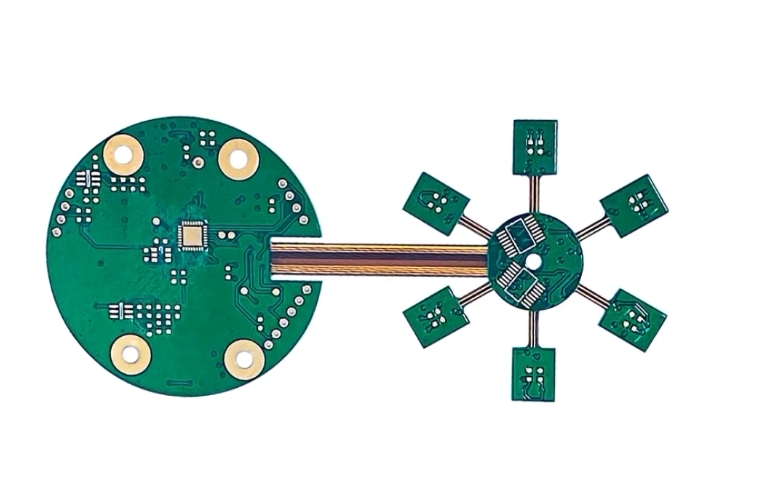

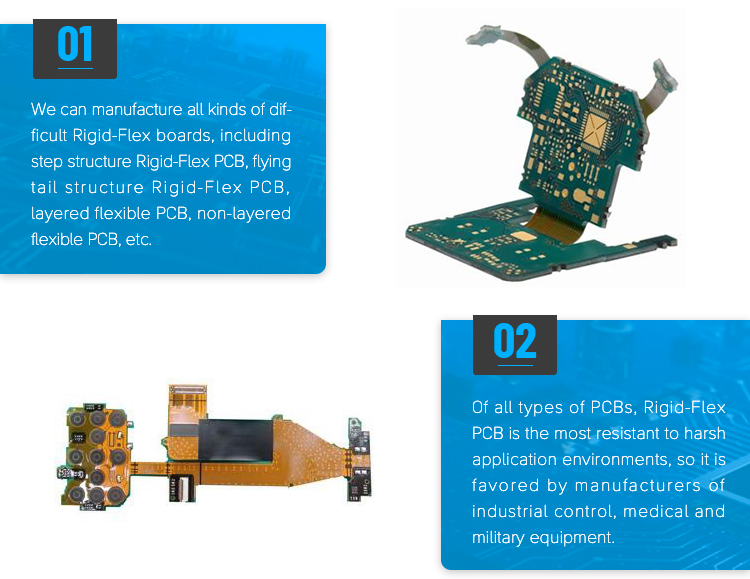

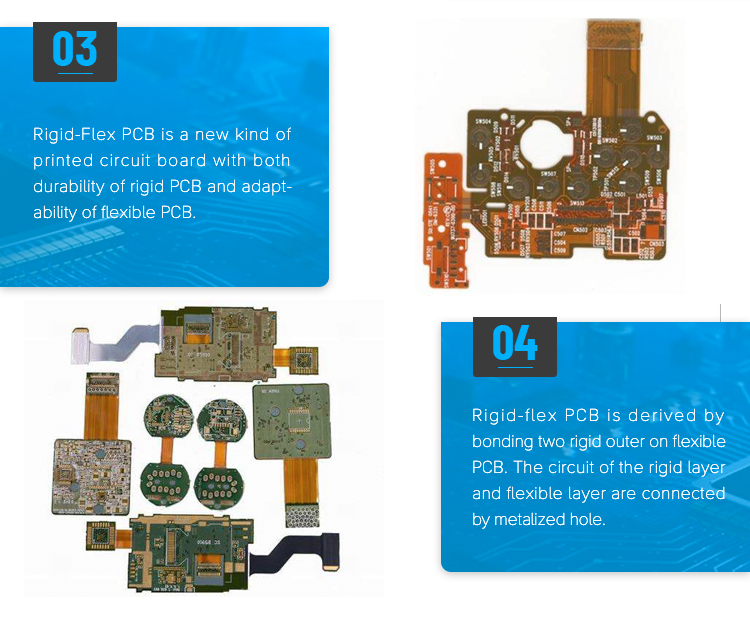

Advanced Rigid-Flex PCB Manufacturing Expertise

We specialize in producing high-performance Rigid-Flex PCBs, including complex designs such as:

- Step Structure Rigid-Flex PCBs

- Flying Tail Structure Rigid-Flex PCBs

- Layered Flexible PCBs

- Non-Layered Flexible PCBs

Among all PCB types, Rigid-Flex PCBs offer superior durability in harsh operating environments. This makes them the preferred choice for mission-critical applications in industrial control systems, medical devices, and military equipment.

Our advanced manufacturing capabilities ensure reliable, high-quality solutions tailored to demanding industry requirements.

Rigid-Flex PCB is a new kind of printed circuit board with the durability of rigid PCB and the flexibility of flexible PCB.

Rigid-flex PCB is derived by bonding two rigid outer on a flexible PCB. The circuit of the rigid layer and flexible layer is connected by the metalized hole.

Why choose us?

1. One-stop PCB PCBA Service

We can help you with a one-stop service. To support you with the whole process from function research and development, product design discussion, PCB manufacturing, component procurement, to PCB assembly.

2. Advanced Equipment

There are more than 385 equipment, mainly imported from Germany, Japanand Taiwan. Such as LDl automatic exposure machine, automatic plating line, laser drilling machine, automatic testing machine, automatic V-cutting machineand other advanced equipment.

3. Advanced Technology

There are more than 28 employees of our R&D team, including 2 doctoral students and 8 master’s students. We can do a 3-step HDI PCBand 0.4mm pitch hole. The technology is in the leading position in the industry.

4. Superior Service

7*24-hour online service! We have a professional service team to follow the whole process for key customers and key orders. Also, we have a professional account manager for each customer to meet the customer’s various demands.