Description

Product Overview

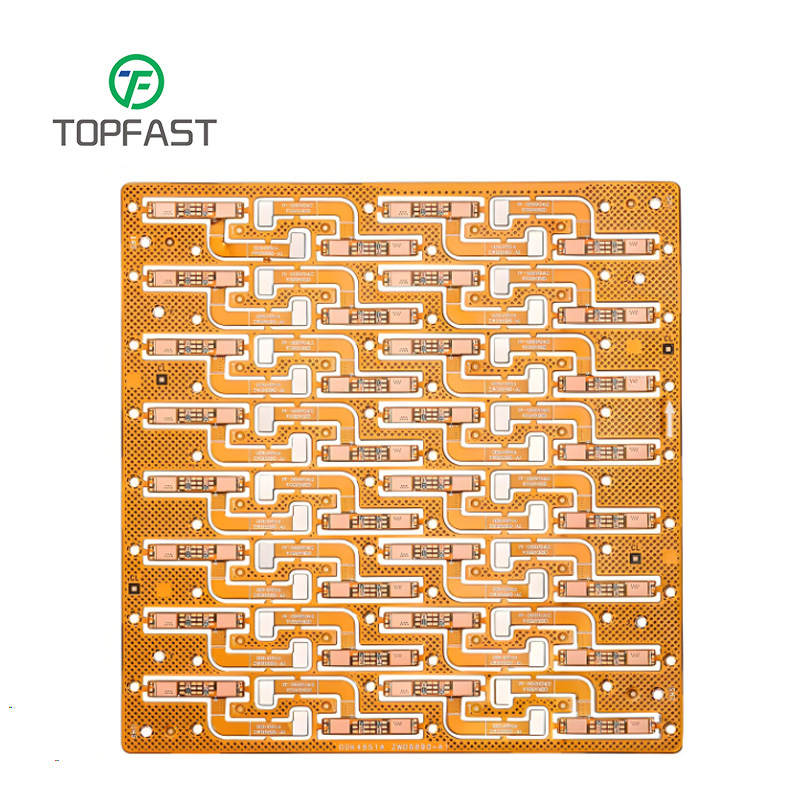

Multilayer Flexible Printed Circuit Boards (Multilayer FPCs) are high-performance interconnect components composed of alternating layers of flexible substrates and conductive copper. Compared to single/double-sided FPCs, multilayer FPCs enable more complex circuit designs through interlayer connections (e.g., laser drilling, plated through-holes), making them suitable for high-density, high-reliability electronic devices.

Multilayer FPCs are widely used in consumer electronics, automotive electronics, medical devices, aerospace, and 5G communications, meeting demands for miniaturization, lightweight design, and bendability.

Flexible PCB Parameters

| Item |

Flexible PCB |

| Max Layer |

8L |

| Inner Layer Min Trace/Space |

3/3mil |

| Out Layer Min Trace/Space |

3.5/4mil |

| Inner Layer Max Copper |

2oz |

| Out Layer Max Copper |

2oz |

| Min Mechanical Drilling |

0.1mm |

| Min Laser Drilling |

0.1mm |

| Aspect Ratio(Mechanical Drilling) |

10:1 |

| Aspect Ratio(Laser Drilling) |

/ |

| Press Fit Hole Ttolerance |

±0.05mm |

| PTH Tolerance |

±0.075mm |

| NPTH Tolerance |

±0.05mm |

| Countersink Tolerance |

±0.15mm |

| Board Thickness |

0.1-0.5mm |

| Board Thickness Tolerance(<1.0mm) |

±0.05mm |

| Board Thickness Tolerance(≥1.0mm) |

/ |

| Impedance Tolerance |

Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

| Differential:±5Ω(≤50Ω),±10%(>50Ω) |

| Min Board Size |

5*10mm |

| Max Board Size |

9*14inch |

| Contour Tolerance |

±0.05mm |

| Min BGA |

7mil |

| Min SMT |

7*10mil |

| Surface Treatment |

ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask |

Green Solder Mask/Black PI/Yellow PI |

| Min Solder Mask Clearance |

3mil |

| Min Solder Mask Dam |

8mil |

| Legend |

White,Black,Red,Yellow |

| Min Legend Width/Height |

4/23mil |

| Strain Fillet Width |

1.5+0.5mil |

| Bow & Twist |

/ |

Product Features

-

High-Density Wiring

-

Utilizes fine-line technology (line width/spacing as low as 30/30μm) and blind/buried vias to enhance circuit integration.

-

Suitable for chip-scale packaging (CSP), high-pin-count BGAs, and other precision components.

-

Excellent Flexibility

-

Uses polyimide (PI) or liquid crystal polymer (LCP) substrates, allowing repeated bending (dynamic applications can withstand millions of cycles).

-

Supports 3D installation, adapting to complex spatial layouts.

-

High Reliability and Stability

-

Resistant to high temperatures (PI substrates can withstand reflow soldering above 260°C) and chemical corrosion.

-

Low dielectric loss, ideal for high-frequency and high-speed signal transmission (e.g., 5G mmWave).

-

Lightweight and Thin Design

-

Thickness can be controlled below 0.1mm, weighing over 70% less than rigid PCBs.

-

Suitable for weight-sensitive applications such as wearables and foldable smartphones.

Product Advantages

| Comparison |

Multilayer FPC |

Traditional Rigid PCB |

Single/Double-Sided FPC |

| Flexibility |

Excellent (dynamic bending) |

None |

Good (static bending) |

| Wiring Density |

Very high (multilayer interconnects) |

High |

Moderate |

| Weight |

Extremely light |

Heavy |

Light |

| High-Frequency Performance |

Excellent (LCP substrate) |

Good |

Average |

| Cost |

Higher (complex process) |

Low |

Moderate |

Manufacturing Process

Multilayer FPC production is more complex than standard PCBs, with critical processes including:

-

Material Preparation

-

Inner Layer Patterning

-

Lamination and Through-Hole Plating

-

Surface Treatment

-

Testing and Validation

-

Flying probe testing (electrical performance)

-

Bend cycle testing (dynamic applications require ≥100,000 cycles)

Applications

-

Consumer Electronics

-

Automotive Electronics

-

Medical Devices

-

Industrial & Communications

-

Aerospace

Frequently Asked Questions (FAQ)

Q1: What file formats do you accept for PCB manufacturing?

We support all industry-standard formats, including:

– Gerber (RS-274X)

– PROTEL (99SE & DXP)

– CAM350

– ODB++ (.TGZ)

– Eagle

– Altium Designer

– PADS

Q2: How do you protect my design files and intellectual property?

We take data security extremely seriously. Your design files are:

– Stored on encrypted servers

– Only accessible to your dedicated project team

– Never shared with third parties without your explicit written consent

– Automatically purged after project completion (unless otherwise requested)

Q3: What payment methods do you accept?

We offer flexible payment options:

Electronic Payments:

– PayPal

– AliPay

– Credit Cards (Visa/MasterCard/UnionPay)

Bank Transfers:

– T/T (Telegraphic Transfer)

– Western Union

– L/C (Letter of Credit)

Q4: What are your shipping options?

We provide global logistics solutions:

Express Shipping (1-5 days):

– DHL

– FedEx

– UPS

– EMS

Bulk Shipping:

– Air freight (>300kg)

– Sea freight (Full container options)

– Can accommodate your preferred freight forwarder

Q5: What is your minimum order quantity?

We specialize in both:

– Prototype quantities (1 piece available)

– High-volume production

No minimum order value requirements

Q6: Can we visit your manufacturing facilities?

We welcome client visits to our facilities:

Main Facility:

Shenzhen, China (ISO 9001 certified)

Secondary Facility:

Guangdong Province, China

Please contact us to schedule a tour with our engineering team

Q7: How do you guarantee PCB quality?

Our comprehensive quality assurance includes:

Testing:

– 100% Electrical Testing (Flying Probe & E-Test)

– Automated Optical Inspection (AOI)

Certifications:

– IPC Class 2/3 standards

– ISO 9001:2015 certified

– UL certified (upon request)

Additional Services:

– Free DFM analysis

– 3D model verification

– Cross-section analysis available

All PCBs come with our quality guarantee and full traceability documentation.