Description

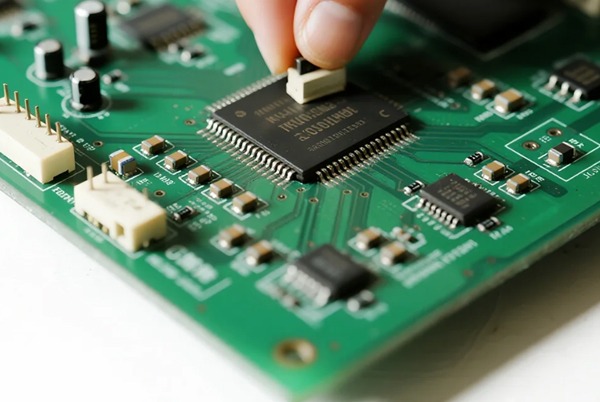

Through-hole technology (THT) has a key role in electronic applications. Its reliability and strong mechanical connections make it essential. Topfast offers specialized through-hole PCB assembly services. These PCBs are perfect for harsh environments. They can withstand mechanical stress, vibration, high temperatures, high pressure, and impact.

In contrast to surface mount technology (SMT), THT offers a more robust structural grip for heavy-duty components. This includes transformers, high-capacity capacitors, and connectors. THT acts as a vital safeguard for system performance and safety.

Our Through-Hole PCB Assembly Capabilities

Comprehensive Component Compatibility

We support various through-hole components, including:

– Axial and radial lead components

– Large transformers and inductors

– High-power resistors and capacitors

– Various connectors and headers

– Special-function modules and custom components

Advanced Insertion and Soldering Techniques

We offer flexible production methods to meet diverse customer needs:

– Automated insertion: Ideal for high-volume production, ensuring consistency and efficiency

– Manual insertion: Suitable for prototyping and small-batch complex designs

– Selective soldering: Precise soldering for sensitive and high-temperature components

– Wave soldering: A traditional yet reliable mass-production soldering solution

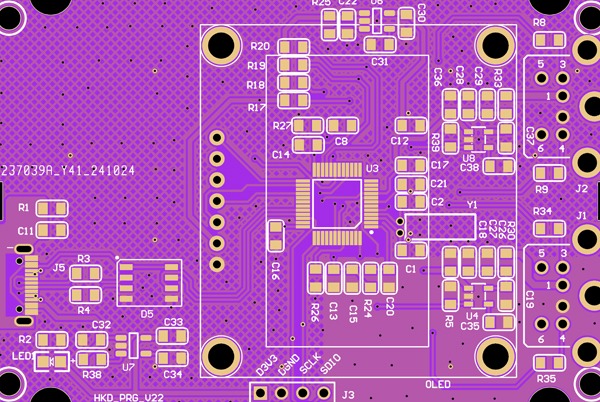

Diverse Material Support and Design Flexibility

Our services support various PCB designs and materials:

– Single-sided, double-sided, and multi-layer boards (up to 64 layers)

– Mixed-technology designs (through-hole combined with SMT)

– FR4, high-Tg FR4, halogen-free laminates, and Rogers high-frequency materials

– Copper thickness up to 1000μm, meeting high-current application requirements

– Multiple surface finish options: ENIG, HASL, OSP, immersion silver, and immersion tin

Get a Free Design Consultation Now

Advantages and Applications of Through-Hole Assembly

Unmatched Mechanical Strength

Through-hole technology provides the strongest physical connection, with component leads passing through board layers and being soldered in place, offering far greater mechanical strength than surface-mount technology. This makes it ideal for environments with vibration, shock, and continuous motion.

Excellent Thermal Management and Power Handling

Through-hole connections offer lower thermal resistance and better heat dissipation, handling higher current loads and temperature fluctuations. This is critical for power conversion, motor control, and power regulation applications.

Broad Environmental Adaptability

Through-hole assembled components perform exceptionally well in harsh environments, resisting:

– Extreme temperature cycling (-55°C to 125°C)

– High humidity and corrosive conditions

– Mechanical vibration and shock

– High-altitude and vacuum conditions

Key Application Areas

1. Power and High-Voltage Systems

Power electronics, power supplies, converters, and high-voltage control systems rely on through-hole technology to handle high currents and voltages.

2. Automotive Electronics

Engine control units (ECUs), transmission controls, battery management systems, and in-vehicle infotainment systems require reliable connections in environments with vibration and temperature variations.

3. Industrial Control Systems

Factory automation, robotic controls, PLC systems, and industrial computers depend on the durability of through-hole technology in harsh industrial environments.

4. Medical Devices

Life support systems, diagnostic equipment, and medical monitoring instruments require absolute reliability, which through-hole technology provides as a critical safety assurance.

5. Aerospace and Defense

Flight control systems, navigation equipment, communication systems, and weapon systems must operate reliably under extreme conditions.

Explore Our Industry Solutions

Our Quality Assurance System

Comprehensive Testing and Inspection Processes

We implement a multi-tier quality control system to ensure every product meets the highest standards:

Optical Inspection

– Automated Optical Inspection (AOI): High-speed, high-precision inspection of solder joint quality and component placement

– Manual Visual Inspection: Experienced technicians review critical areas

Electrical Testing

– In-Circuit Testing (ICT): Verifies circuit connectivity and basic functionality

– Flying Probe Testing: A flexible testing solution for small batches and prototype boards

Functional Testing

– Fully simulates end-use environments

– Stress testing and boundary condition validation

– Long-term reliability and aging tests

X-Ray Inspection

– Examines hidden solder joints and BGA components

– Analyzes solder joint integrity and internal structures

– Inspects hole wall quality and copper plating uniformity

Certifications and Standards Compliance

Our processes comply with international standards and certifications:

– IPC-A-610 Class 2/3 Acceptance Criteria

– ISO 9001:2015 Quality Management System

– IATF 16949 Automotive Quality Standard

– RoHS and REACH Environmental Directives

– UL Certification and Safety Standards

Why Choose Topfast for Through-Hole PCB Assembly?

Extensive Industry Experience

Since 2007, we have provided reliable electronics manufacturing services to over 3,000 global clients, accumulating deep expertise in through-hole assembly.

Reliable Supply Chain Management

We maintain direct partnerships with globally renowned component suppliers to ensure genuine parts:

– Mouser Electronics

– Digi-Key Electronics

– Future Electronics

– WPG Holdings

Flexible Production Capacity

We support end-to-end services from prototyping to mass production:

– Rapid prototyping (fastest 24-hour turnaround)

– Small-batch pilot runs (50–1,000 units)

– Medium to high-volume production (10,000+ units)

– Mixed-technology assembly (through-hole + SMT)

Technical Support and Design Optimization

Our engineering team provides full design support:

– DFM (Design for Manufacturability) Analysis

– DFA (Design for Assembly) Optimization

– Thermal Management and Signal Integrity Analysis

– Cost Optimization and Alternate Component Suggestions

One-Stop Solution

We offer complete integrated manufacturing services:

– PCB fabrication and assembly

– Component sourcing and management

– Harness and cable assembly

– Conformal coating and encapsulation

– Final product assembly and testing

Request an Instant Quote

Our Service Process

1. **Consultation & Needs Analysis** – Our engineers discuss your specific requirements and challenges.

2. **Design Review & Optimization** – Professional design improvement suggestions.

3. **Quotation & Planning** – Transparent pricing and clear timelines.

4. **Material Procurement** – Sourcing high-quality components from reliable channels.

5. **Manufacturing & Assembly** – Utilizing the latest equipment and process technologies.

6. **Comprehensive Testing** – Multi-layered quality assurance processes.

7. **Delivery & Support** – On-time delivery and ongoing after-sales service.

Frequently Asked Questions

Q: Is through-hole technology obsolete in modern electronics?

A: Not. While SMT dominates miniaturized applications, through-hole technology remains irreplaceable in applications requiring high reliability, mechanical strength, and power handling.

Q: What is the minimum order quantity (MOQ)?

A: We offer flexible order options. Prototyping can start from 1 unit, while production orders typically begin at 50 units, depending on complexity.

Q: What is the typical lead time?

A: Prototype projects can be completed in as fast as 3–5 days. Production orders usually take 2–4 weeks, depending on project complexity and order volume.

Q: Do you support mixed-technology (through-hole + SMT) assembly?

A: Yes, we specialize in mixed-technology assembly, optimizing processes for the best quality and efficiency.

Contact Us for More Information

Start Your Project

Whether you need prototyping or large-scale production, Topfast has the expertise, equipment, and technology to meet your through-hole PCB assembly needs. Our team is ready to provide technical support, design optimization, and manufacturing solutions.

Take Action Now:

– Send your design files for a free DFM analysis

– Schedule a technical meeting to discuss your project requirements

– Request a personalized quote and delivery timeline

Let’s collaborate to create reliable, durable, and high-performance electronic solutions that give your products a competitive edge and market success.