الوصف

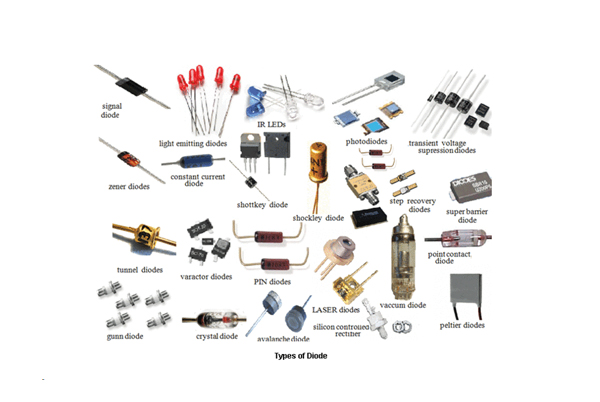

باعتبارها أكثر مكونات أشباه الموصلات الأساسية والأكثر أهمية، تُستخدم الثنائيات في كل دائرة تقريبًا، بدءًا من تصحيح الطاقة البسيط إلى معالجة الإشارات المعقدة عالية التردد. يؤثر أداء الثنائيات بشكل مباشر على موثوقية وكفاءة النظام الإلكتروني بأكمله. وبفضل 17 عامًا من الخبرة كخبير في تصنيع ثنائي الفينيل متعدد الكلور، تقدم Topfast حلولاً عالية الجودة ومتكاملة لثنائي الفينيل متعدد الكلور لضمان تحقيق تصميماتك الأداء الأمثل بدءًا من المكونات وحتى اللوحات النهائية.

أهمية اختيار الصمام الثنائي

تتحكم الثنائيات في التدفق أحادي الاتجاه للتيار في الدوائر الإلكترونية.قد يؤدي اختيار الدايود الخاطئ إلى

-

كفاءة طاقة منخفضة (انخفاض مفرط في الجهد الأمامي عند استخدام ثنائيات المعدل القياسية بدلاً من ثنائيات شوتكي)

-

عدم استقرار النظام (الضرر الكهروستاتيكي بسبب عدم كفاية حماية الصمام الثنائي TVS)

-

تدهور سلامة الإشارة (اختيار الصمام الثنائي النقطي غير المناسب في التطبيقات عالية التردد)

-

انخفاض العمر الافتراضي للمنتج (تشغيل غير مستقر من اختيار الصمام الثنائي Zener diode غير الصحيح)

كثيرًا ما نواجه عملاء يطلبون المساعدة في تصميمات ثنائي الفينيل متعدد الكلور الفاشلة، حيث يعود السبب الجذري غالبًا إلى اختيار الصمام الثنائي غير المناسب. على سبيل المثال، استخدمت إحدى الشركات المصنعة لمعدات التحكم الصناعية في البداية ثنائيات مقوم قياسي، مما أدى إلى كفاءة وحدة الطاقة بنسبة 78% فقط. وبعد توصيتنا المهنية بالتبديل إلى ثنائيات شوتكي منخفضة التردد، تحسنت الكفاءة إلى 92%، مع انخفاض في ارتفاع درجة الحرارة بمقدار 15 درجة مئوية.

مزايا شراء الصمام الثنائي الاحترافي لدينا

وباعتبارنا مزوداً شاملاً لحلول ثنائي الفينيل متعدد الكلور، فقد أنشأنا شبكة توريد الصمام الثنائي القوي، ونقدم

-

دعم الصمام الثنائي كامل الفئة: تغطي أكثر من 2000 نموذج، بدءًا من ثنائيات PN-junction ثنائيات PN الأساسية إلى ثنائيات PIN ثنائية متخصصة وثنائيات متغيرة.

-

قنوات الموردين المعتمدين: تضمن الشراكات مع العلامات التجارية الرائدة مثل ON Semiconductor وVishay وDiodes Inc.

-

خدمة المطابقة التقنية: يوصي فريقنا الهندسي بأنسب أنواع الصمامات الثنائية بناءً على تطبيقك (الطاقة/الإشارة/الحماية).

-

حلول تحسين التكلفةبالنسبة للإنتاج بكميات كبيرة، نقدم اقتراحات نماذج بديلة لتقليل تكاليف قائمة المواد الأولية دون المساس بالأداء.

بعد شراء المكونات، يجب تركيبها بشكل مثالي على لوحة PCB. تصميم ثنائي الفينيل متعدد الكلور مهم جدًا أيضًا، لأنه يؤثر على استقرار المنتج النهائي وموثوقيته. وتشمل خدمات القيمة المضافة التي نقدمها ما يلي:

-

تحليل التصميم الحراري: تحسين وضع الصمام الثنائي المقوم للتيار العالي لمنع السخونة الزائدة الموضعية.

-

محاكاة تكامل الإشارةتقييم تأثير صمامات شوتكي الثنائية عالية السرعة على جودة الإشارة.

-

حلول الحماية من التفريغ الكهرومغناطيسي: تصميم شبكات حماية الصمام الثنائي TVS للدوائر الحساسة.

-

مراجعة قابلية التصنيعضمان توافق تغليف الصمام الثنائي مع عمليات ثنائي الفينيل متعدد الكلور.

في مشروع إلكترونيات سيارات حديث، أعدنا تصميم تخطيط الصمام الثنائي في دائرة محرك LED، مما أدى إلى تحسين إنتاجية الإنتاج من 83% إلى 99.6%.بالإضافة إلى ذلك، من خلال تحسين اختيار الصمام الثنائي Zener، زادت دقة تنظيم الجهد بنسبة 30%.

حلول الصمام الثنائي الخاصة بالصناعة

تتطلب التطبيقات المختلفة متطلبات الصمام الثنائي الفريدة من نوعها:

إلكترونيات السيارات:

-

ثنائيات ثنائية متوافقة مع AEC-Q101 المتوافقة مع معايير AEC-Q101 الخاصة بالسيارات

-

حلول الحماية من الصمام الثنائي TVS عالي المقاومة للاهتزازات

-

ثنائيات مقوم شوتكي ثنائية شوتكي ذات نطاق درجة حرارة واسعة (-40 درجة مئوية إلى 150 درجة مئوية)

التحكم الصناعي:

-

حلول SCR (المقوم المتحكم فيه بالسيليكون) ذات التيار العالي

-

صمامات ثنائيات الصمامات الثنائية ذات الجهد العالي العازل الضوئي

-

مصفوفات الصمام الثنائي السريع الاسترداد المقاوم للتداخل الكهرومغناطيسي

الأجهزة الطبية:

-

ثنائيات الإشارة الدقيقة منخفضة التسرب

-

صمامات العزل الثنائية المتوافقة مع السلامة الطبية

-

ثنائيات زينر ثنائية عالية الموثوقية لمعدات دعم الحياة

منتجات إنترنت الأشياء:

-

تحسين الصمام الثنائي الجسمي MOSFET منخفض الطاقة للغاية

-

حلول الصمام الثنائي الضوئي لحصاد الطاقة

-

مكونات الصمام الثنائي المصغر (SOD-323، إلخ)

حل شامل من النموذج الأولي إلى الإنتاج الضخم

نحن ندرك أن تطوير الإلكترونيات هو عملية تكرارية، ونقدم دعمًا مرنًا:

-

مرحلة وضع النماذج الأولية:

-

التوريد السريع لدفعات صغيرة ومتعددة الأصناف من الصمامات الثنائية الثنائية

-

اختبار العينات الهندسية المجاني

-

مراجعة تصميم ثنائي الفينيل متعدد الكلور ونصائح اختيار الصمام الثنائي الفينيل متعدد الكلور

-

مرحلة الإنتاج التجريبي:

-

تقييم مخاطر سلسلة التوريد والحلول الاحتياطية

-

اختبار اتساق معلمة الصمام الثنائي

-

دعم تطوير تركيبات اختبار الإنتاج

-

مرحلة الإنتاج الضخم:

-

ضمان إمداد الصمام الثنائي المستقر طويل الأجل

-

إمكانية تتبع الدفعات وتوثيق الجودة

-

الخفض المستمر للتكاليف والحلول البديلة

أثبتت حالة أحد عملاء المنازل الذكية أن خدمات الدورة الكاملة التي نقدمها قللت من وقت انتقال المنتج من النموذج الأولي إلى الإنتاج الضخم بنسبة 40%، وقضت على مشكلات الجودة المتعلقة بالديود وخفضت تكاليف الشراء بنسبة 22%.

في قطاع تصنيع الإلكترونيات التنافسي، نقدم في قطاع تصنيع الإلكترونيات التنافسية مدفوعة بالتكنولوجيا الخدمات:

-

17 عاماً من الخبرة المتخصصة: خدمت أكثر من 3800 عميل، وأنجزت أكثر من 15000 مشروع متعلق بالديود.

-

شهادة UL/ISO9001: رقابة صارمة على الجودة تضمن موثوقية الصمام الثنائي.

-

النماذج الأولية السريعة في 48 ساعة: دعم المشروع في حالات الطوارئ، بما في ذلك شراء الصمام الثنائي الصمام الثنائي الفينيل المتعدد الكلور وتصنيع ثنائي الفينيل متعدد الكلور.

-

الشبكة اللوجستية العالمية: التسليم في الوقت المحدد (JIT) لتقليل الضغط على مخزون العميل.

-

فريق الخبراء الهندسيين: يقدم الدعم الفردي من قِبل خبراء في مجال الصناعة يتمتعون بخبرة 10 سنوات في المتوسط.

نحن ندرك أن التصنيع الاستثنائي لثنائي الفينيل متعدد الكلور لا يتطلب معدات متطورة فحسب، بل يتطلب أيضًا خبرة عميقة في المكونات.إن معرفتنا الشاملة بخصائص الصمام الثنائي تمكننا من تقديم حلول قيّمة حقًا، وليس فقط تصنيع لوحات الدارات الكهربائية.

بغض النظر عن مرحلة تطوير منتجك، فإن فريق الخبراء لدينا على استعداد لمساعدتك.أرسل متطلباتك واحصل على:

-

الاقتراح الأولي وعرض الأسعار في غضون 1 ساعة

-

ملاحظات الجدوى الهندسية ضمن 4 ساعات

-

خطة تنفيذ المشروع بالكامل ضمن 24 ساعة

بالنسبة للمشاريع المعقدة، نقوم بترتيب اجتماعات فنية في الموقع لاستكشاف تطبيقات الصمام الثنائي الأمثل. دع خبرتنا الاحترافية في الصمام الثنائي المحترف وخبرتنا في تصنيع ثنائي الفينيل متعدد الكلور تحمي تصميماتك الإلكترونية.