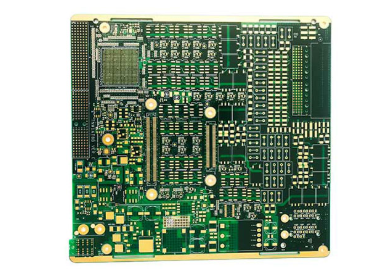

Here is Rigid Pcb Manufacturer talking about The Consumable Parts On The Board During Maintenance.

If you have any idea about Pcb Buried Components, welcome to contact us and discuss.

1. The most unreasonable design is the most troublesome

Any circuit board can't be perfected in design, and it has its own inherent defects and deficiencies. This is innate. When the equipment leaves the factory, it implies a certain fault that must occur when it is used. The weakness of these structures is sometimes the immaturity of the design. Sometimes the quality of the selected materials is not enough. Does the manufacturer know the weaknesses of this structure? Some know it, but it is unavoidable.

Why do you say this? First of all, this is a question of whether the so-called fish and bear's paw can have both. In general, the better the quality of the device, the larger the component, the better, because the larger the component, the thicker the pin, the stronger it is. In reality, people are demanding smaller and more devices, more and more functions, and more power. The larger, the more contradictory; secondly, the longer the design time, the more the product will be perfect, but in fact, the manufacturer can't do it, and the product update speed is getting faster and faster. The faster the update, the more time the vendor has to test the performance of the product, the sacrifice is the quality of the product. Moreover, from another perspective, the production of equipment that is not bad for decades means the bankruptcy of the manufacturers. For our maintenance industry, repairing the boards that are not bad for decades means unemployment. So, what is the unreasonable design of industrial boards? The first is the heat dissipation problem. Many circuit board damages are caused by poor heat dissipation design, followed by the copper foil wire of the printed board. The copper foil of the poor quality circuit board power supply line is very thin, and it is easy to blow due to overcurrent. So that the motherboard can not work.

2. The use of frequent places is prone to failure

When repairing VCDs and DVDs, home appliance masters know that as long as the machine does not read the disk, it is a bad laser head, because the bald head needs to be illuminated, focused, tracked, and left and right to feed. As long as the machine works, it will Busy, this kind of "willing to sacrifice" spirit will one day "sick down", the same circuit board, for example, industrial circuit board drive motor, shaft, switch power supply switch, common buttons on the operation panel, etc.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China