High TG PCB is a plate with high glass transition temperature. High Tg means high heat resistance. We all know that if electronic products often work for a long time, the heat generated during the working process will be transferred to other components, which will eventually affect the durability and performance of the product. If your PCB works at high temperatures for a long time, you'd better choose high TG materials.

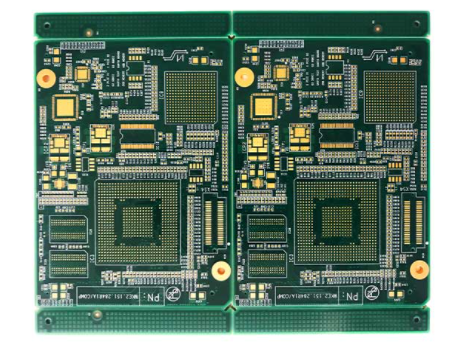

With the rapid development of electronic industry, high Tg materials are widely used in computers, communication equipment, precision instruments and instruments. In order to achieve high-function, high multi-layer development, PCB substrate materials need higher heat resistance as a prerequisite. Moreover, due to the emergence and development of high-density installation technology represented by SMT and CMT, in the case of thinning, small aperture and fine wiring, the high heat resistance of the substrate and the substrate are more and more inseparable. Therefore, the difference between general FR-4 and high FR4-Tg is that mechanical strength, adhesion, water absorption, dimensional stability and thermal decomposition in hot state are different under different conditions. It is obvious that high Tg PCB is better than ordinary PCB substrate materials. Therefore, there is a great demand for high Tg PCB in recent years, but the price is higher than that of ordinary PCB.

More importantly, high Tg materials are also popular in the LED lighting industry because the hat dissipation rate of LED is higher than that of ordinary electronic components, but the same structure of FR- 4 plates is much cheaper than metal core PCB such as aluminum core PCB.

Higher stability: if you increase the Tg of the PCB substrate, it will automatically improve the heat resistance, chemical resistance, moisture resistance and device stability.

Withstand high power density design: if the device has high power density and fairly high calorific value, then high Tg PCB will be a good solution for thermal management.

When reducing the heat generation of ordinary boards, larger printed circuit boards can be used to change the design and power requirements of the equipment, and a high Tg PCB can also be used.

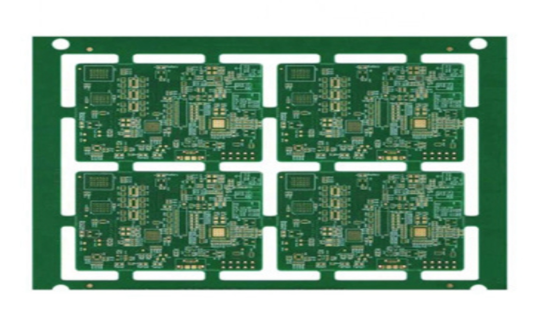

Ideal for multilayer and HDI PCB: because multilayer and HDI PCB are more compact and circuit-dense, they will result in high levels of heat dissipation. Therefore, high Tg PCB is commonly used in multi-layer and HDI PCB to ensure the reliability of PCB manufacturing.

Standard PCB is usually made of materials with a TG value of 140C and can withstand an operating temperature of 110C. However, the standard PCB may not be suitable for the extreme temperature environments common in industrial, automotive and other high temperature electronic applications. When it comes to these situations, FR4 materials will be the best solution.

If your printed circuit board cannot withstand a heat load of no less than Tg 25 degrees Celsius, your application will require a high Tg PCB. In addition, it ensures the safety of using high Tg PCB if your product operates in a temperature range of 130C or higher. Needless to say, the main reason for high Tg PCB is the shift to RoHS PCB. As a result, more and more PCB industries are turning to high-Tg materials because higher temperatures are needed for lead-free solders to flow.

If the power density in the electronics is higher, and the heating interferes with the radiator or other parts of the product, then a high TgPCB is the best solution. In addition, with the popularity of high Tg PCB in recent years, you will find that Tg PCB is used in the electronics industry that can operate at higher temperatures. Therefore, we can meet the needs of customers in different industries by providing high Tg PCB with high heat resistance, and these PCB can meet customer specifications in a short delivery time. Therefore, they are examples of applications, as follows: Gateway, radio frequency identification, inverter, antenna board, wireless booster, contract manufacturing service, low-cost PLC, embedded system development, embedded computer system, AC power supply.

Please contact TOPFAST if you need to buy them and we offer great service.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China