Flexible PCB is a special type of printed circuit board that uses a thin and bendable polyimide (PI) substrate instead of a rigid FR4/metal/PTFE/ceramic substrate and a PI overlay instead of a solder resist layer.

Compared with ordinary rigid PCB boards, flexible flex PCBs are widely used in telecommunications, automotive, industrial, medical, defense, aerospace, consumer electronics and other electronic devices and systems. Why are flexible PCBs so popular? Let's take a look.

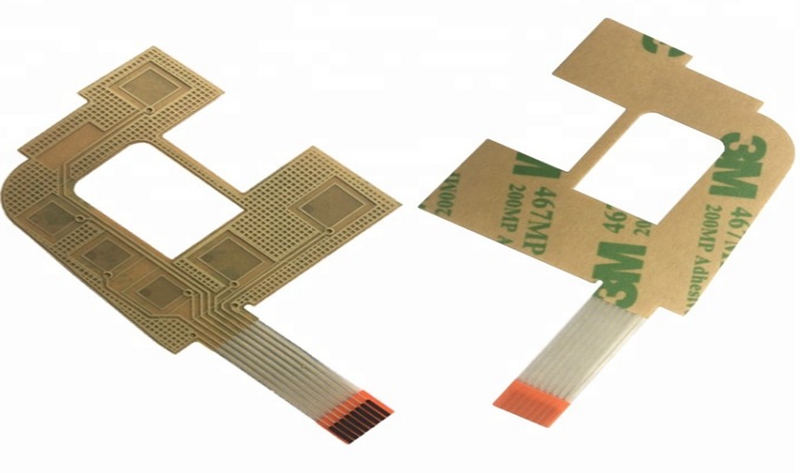

Flexible PCB is also known as flexible circuit board, flexible PCB, FPC. copper circuit traces are etched on a non-conductive flexible polyimide material, and the different circuit layers are interconnected by plated through holes (PTH) or buried holes. On both sides of the flexible PCB, electronic components can be surface mounted on the PCB pads. For better mechanical support, sometimes PCB stiffeners can be added to the end of the flexible PCB for connection to systems/devices/other components.

PI substrate - PI substrate is the core of FPC. PI material is usually yellow, but it can also be black, white and transparent.

Calendered copper foil - the etched copper foil is the circuit layer of the flexible PCB. Rolled copper foil significantly improves the ductility and repeatable bendability of FPCs.

PI layer - The PI layer insulates the copper circuit layer and is made of the same material as the substrate, only smaller in thickness

Adhesive layers- For flexible PCBs, adhesive layers are optional. They are located between the copper layer and the PI layer to bond them.

Flexible PCB vias - PCB vias are laser drilled through the FPC layers and interconnect the different circuit layers.

Flexible PCB Reinforcement - A reinforcement is a rigid piece laminated to the end of a flexible PCB for connection to the system/device interface.

Depending on the number of line layers, there are single-layer FPC, two-layer FPC, and multi-layer FPC.

Depending on the component placement surface, there are single-sided FPC, double-sided FPC.

According to the different of FPC laminate, there are yellow polyimide FPC, transparent flexible PCB, flexible aluminum PCB.

According to the different of FPC over hole, there are HDI flexible PCB, ordinary flexible PCB.

Flexible PCBs can be used in almost all electrical and electronic industries. However, flexible PCBs are more expensive than ordinary rigid PCBs, and they have been widely used in the following industries.

Flexible PCBs are used in automotive systems/parts, including anti-lock braking systems, airbag controllers, instrument panel systems, instrument panels, etc. Flexible PCBs are suitable for small parts and provide flexibility for engineers.

Flexible PCBs are used in different parts of the aerospace industry, such as holographic waveguide helmet displays used to provide high-resolution 3D images. In satellites, flexible PCBs are used to replace connectors that can lead to interconnection errors, they can be folded and bent thousands of times to carry components and directly connect different parts.

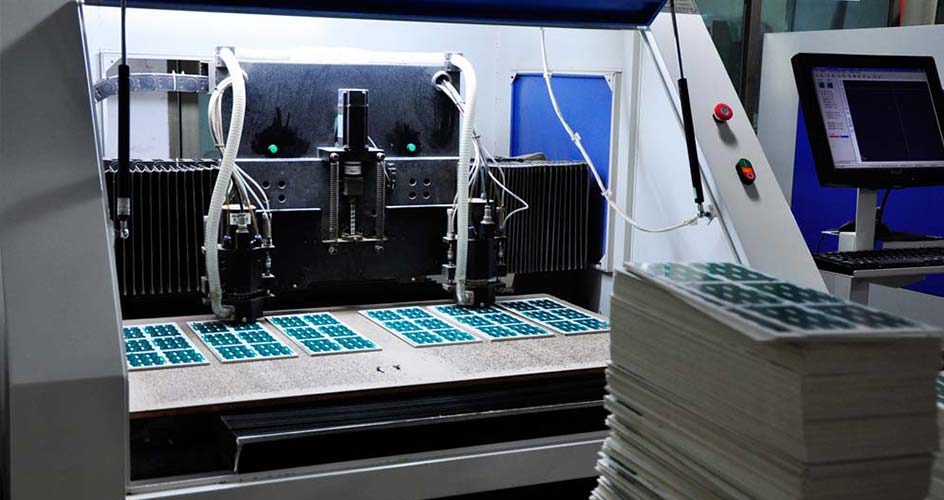

PCB Equipment, CNC machine

Computer operations rely on flexible PCBs because of the small space for computers and flexible PCBs to transmit signals. Desktop computers usually use 4-layer and 6-layer FPC boards, and laptops with less space require 8-layer FPC boards.

Smartphones are small, lightweight, portable and multifunctional. Inside small smartphones, there are a large number of flexible PCBs used to carry and connect various components. flexible PCBs fit into small spaces and ensure the safety of our smartphones, and they are heat and environmental resistant.

TOPFAST is a professional PCB manufacturer, we provide one-stop service and customization for you. We will continue to focus on customer satisfaction, along with "high quality “and "fast delivery", we will become a PCB service provider worthy of customer trust. if you need, please contact us by email.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China