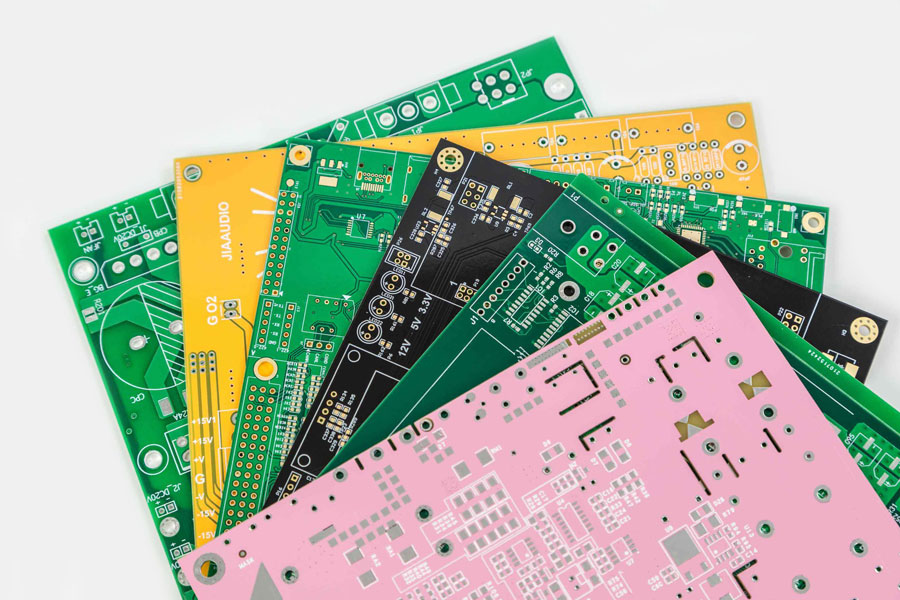

PCB COLORS:

PCB boards typically come in a variety of colors, although the most common color is green. The color of a PCB board is determined by the solder mask, which is a protective layer applied to the surface of the board. The solder mask helps to insulate and protect the copper traces and components on the PCB.

Here are some of the commonly used colors for PCB boards:

Green: Green is the most common color for PCB boards. It has been traditionally used for many years and is associated with standard PCBs.

Red: Red is another popular color for PCB boards. It is often used for high-visibility applications or to differentiate specific types of circuits.

Blue: Blue PCBs are also quite common. They are often used for aesthetic purposes or to differentiate specific functions or product lines.

Black: Black PCBs are less common but are gaining popularity in certain applications. They are often used for high-end or specialized products where aesthetics and visual appeal are important.

White: White PCBs are less common but are sometimes used for specific applications or for products with a unique design requirement.

Yellow: Yellow PCBs are less commonly used compared to colors like green, red, blue, or black.

DIFFERENT COLORS, DIFFERENT USAGES:

For the manufacturing, people always use the different colors for marking the different application areas:

Red PCB boards are usually used in LED strips, power supplies and other electronic products; yellow PCB boards are usually used in radio equipment; green PCB boards are usually used in computer motherboards, graphic cards and other electronic products; blue PCB boards are usually used in industrial control equipment; black PCB boards are usually used in high-end electronic products.

It is important to note that the colour of the PCB board does not have a great impact on its performance and functionality, the different colors of the PCB are mainly designed to distinguish different circuit boards or for aesthetic purposes. PCB board colour has no great effect on its performance, different colors of PCB boards are mainly to distinguish between different circuit boards, branding or special design for aesthetics.

ADVANTAGES FOR DIFFERENT COLORS:

The choice of color for PCBs is primarily based on aesthetics, branding, or specific design requirements. While the color of the PCB board does not affect its functionality or performance, different colors can offer certain advantages in terms of visual appeal, identification, and customization. Here are some advantages associated with different color PCBs:

Green PCBs:

The green color provides good contrast for component placement and is easy to identify.

Standard and widely recognized color for PCBs.

Easy to identify and work with during assembly and troubleshooting.

Cost-effective option as green solder mask is commonly used.

Red PCBs:

Red PCBs can be visually appealing and are commonly used in consumer electronics, automotive, and industrial applications.

High-visibility color that can make the PCB stand out.

Can be used to differentiate specific types of circuits or functions.

Offers a visually appealing and distinctive look.

Suitable for applications where aesthetics and branding are important.

Blue PCBs:

Blue PCBs can give a modern and professional look to electronic devices.

Can be used for aesthetic purposes or to differentiate product lines.

Offers a visually pleasing and unique look.

Suitable for applications where a visually appealing PCB is desired.

Black PCBs:

Black PCBs can provide a sleek and sophisticated appearance.

Offers a high-end and premium look.

Can enhance the overall aesthetics of the electronic device.

Suitable for applications where a premium or luxury feel is desired.

White PCBs:

White PCBs always provide a clean and minimalist look.

Can be used for specific design requirements or unique applications.

Offers a visually striking and distinctive appearance.

Suitable for applications where a clean and minimalist design is desired.

MOST POPULAR GREEN COLOR PCBS:

Green PCBs are the most commonly used color for several reasons:

Tradition and Standardization: Green has been the traditional color for PCBs for many years. It has become the standard color due to its long-standing use in the industry. As a result, green PCBs are readily available and widely accepted.

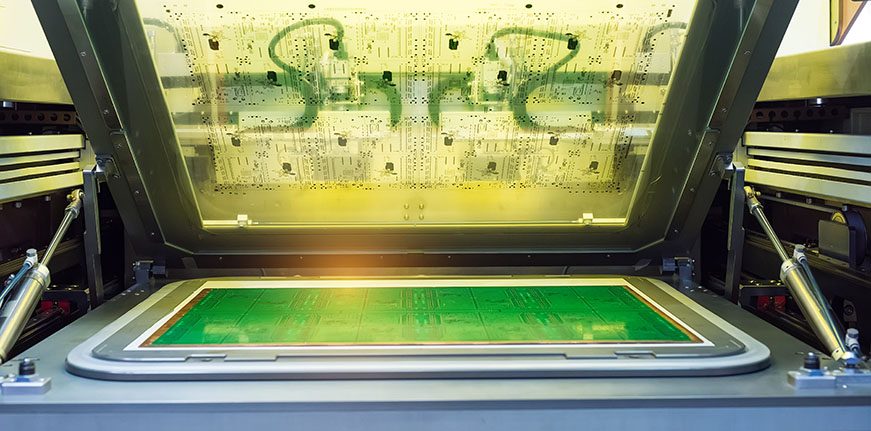

Cost-Effectiveness: Green solder mask is one of the most cost-effective options for PCB manufacturing. The materials used to create green solder mask are generally less expensive compared to other colors, making green PCBs a cost-efficient choice for manufacturers.

Contrast and Visibility: Green solder mask provides good contrast for component placement and identification. The bright green color makes it easier to visually distinguish components and traces on the PCB, aiding in assembly, testing, and troubleshooting processes.

Manufacturing Processes: Green solder mask is compatible with standard PCB manufacturing processes. Manufacturers have optimized their processes for green PCBs, ensuring efficient production and consistent quality.

Familiarity and Trust: Green PCBs have gained a reputation for reliability and performance over the years. Many electronic devices, including consumer electronics, have successfully used green PCBs, establishing a sense of familiarity and trust among manufacturers and consumers.

Compatibility with Automated Optical Inspection (AOI): Green solder mask is highly compatible with AOI systems, which are used for automated inspection during PCB assembly. The contrast provided by green solder mask makes it easier for AOI systems to detect and inspect components and solder joints accurately.

While green is the most commonly used color for PCBs, it’s important to note that other colors are also available and can be used based on specific design requirements, branding considerations, or aesthetic preferences. The choice of color ultimately depends on the specific needs and goals of the electronic device being developed.

Topfast is the top-leading manufacturer in China which is expert on PCB fabrication and PCB assembly, for the one-side pcb or double side pcbs, we can deliver your order within 12 hours, you can also custom your pcbs in different colors. Any product requests, please no hesitate to send your requests.

Address of Plant

PCB Factory:

A1 Building, B Zone, Ditang Industrial Zone, Ditang Road, Shajing Street, Bao'an District, Shenzhen, China

PCBA Factory:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China

Office Address:

Room 805, Room 806, Room 809, No. 96, Chuangqiang Road, Ningxi Street, Zengcheng District, Guangzhou City, Guangdong Province, P.R. China