Açıklama

Günümüzün hızlı tempolu elektronik geliştirme ortamında, konsept tasarımdan seri üretime kadar her adım kritik öneme sahiptir. Topfast, 17 yıllık endüstri deneyimine sahip lider bir PCB çözüm sağlayıcısı olarak, kapsamlı profesyonel anahtar teslimi çözümler sunmaktadır. PCB montaj hizmetleriKüresel müşterilerin yenilikçi tasarımları verimli bir şekilde güvenilir ürünlere dönüştürmelerine yardımcı olurken pazara sunma süresini önemli ölçüde kısaltır.

Topfast’ın Profesyonel Anahtar Teslim PCB Montaj Hizmetleri?

Uçtan Uca Eksiksiz Çözüm

Sıradan PCB üreticilerinin aksine Topfast, tasarım incelemesinden son teslimata kadar eksiksiz bir değer zinciri hizmeti sunar. Anahtar teslim hizmetimizi seçtiğinizde şunlardan faydalanırsınız:

-

Profesyonel DFM Mühendislik Desteği: Teknik ekibimiz, proje başlangıcında Gerber dosyalarınızın ve BOM'unuzun derinlemesine Üretilebilirlik için Tasarım (DFM) analizini gerçekleştirerek olası sorunları erkenden belirler ve daha sonra maliyetli yeniden çalışmayı önlemek için optimizasyon önerileri sunar.

-

Yüksek Kaliteli PCB Üretimi: 20.000 metrekarelik fabrikamız, çeşitli endüstri ihtiyaçlarını karşılamak için sert levhalar, esnek levhalar, sert-esnek levhalar, HDI levhalar, RF levhalar ve daha fazlasını üretebilen lazer delme makineleri ve VCP delikli kaplama hatları gibi gelişmiş ekipmanlarla donatılmıştır.

-

Güvenilir Bileşen Tedarik Zinciri: Üst düzey marka üreticileriyle kurduğumuz derin ortaklıklar sayesinde, en rekabetçi fiyatları sunarken bileşen kalitesini de garanti ediyoruz. Küresel tedarikçi ağımız çeşitli bileşen gereksinimlerine hızla yanıt verebilir.

-

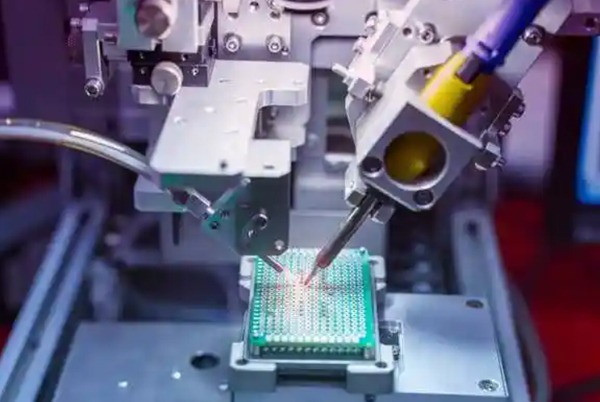

Hassas Montaj Süreçleri: SMT, THT, BGA yeniden işleme ve seçici lehimleme dahil olmak üzere gelişmiş montaj teknolojilerini kullanarak, her lehim bağlantısının IPC-A-610 standartlarını karşılamasını sağlamak için yüksek hassasiyetli yerleştirme makineleri ve profesyonel lehimleme teknikleri ile eşleştirilmiştir.

Titiz Kalite Güvence Sistemi

ISO 9001, ISO 13485 ve UL sertifikalı profesyonel bir üretici olarak Topfast, tüm üretim süreci boyunca kalite kontrol uygulamaktadır:

-

100 Elektriksel Test: Tüm çıplak kartlar, devre bağlantısını sağlamak için uçan prob veya fikstür testine tabi tutulur

-

Çoklu Denetim Yöntemleri: Kapsamlı PCBA kalite güvencesi için AOI otomatik optik denetim, X-ray denetimi (BGA'lar/gizli lehim bağlantıları için) ve işlevsel testlerin birleştirilmesi

-

Sıkı ESD Kontrolü: Hassas bileşenlerin zarar görmesini önlemek için üretim ortamında eksiksiz elektrostatik koruma önlemlerinin uygulanması

-

Temizlik ve Ambalaj: Montaj sonrası profesyonel temizlik ve güvenli taşıma sağlamak için anti-statik paketleme

Topfast’ın Anahtar Teslim Hizmetlerinin Temel Avantajları

Müşteriler için Operasyonel Karmaşıklığı Önemli Ölçüde Azaltma

Geleneksel modellerde, müşterilerin aşağıdakilerle ayrı ayrı koordinasyon kurması gerekir PCB üreticileribileşen tedarikçileri ve montaj fabrikaları, yüksek iletişim maliyetlerine ve potansiyel hatalara neden olur. Topfast’ın tek elden hizmeti, tasarımdan bitmiş ürüne kadar tüm adımları tamamlamak için yalnızca bir profesyonel ekiple çalışmanız gerektiği anlamına gelir ve yönetim yüklerini büyük ölçüde azaltır.

Verilerimiz, anahtar teslim hizmetleri kullanan müşterilerin proje süresinde ortalama 'un üzerinde tasarruf sağladığını göstermektedir; bu da, ürünleri hızlı bir şekilde pazara sunmak için sınırlı kaynaklara sahip yeni başlayanlar veya KOBİ'ler için özellikle uygundur.

Çeşitli Üretim İhtiyaçları için Esnek Destek

İster ihtiyacınız olsun:

-

Hızlı prototipleme için 5-10 parça

-

Küçük parti pilot üretim için 50-1000 adet

-

Seri üretim için on binlerce parça

Topfast özel çözümler sunabilir. Ürün geliştirmenin çeşitli aşamalarındaki farklı ihtiyaçları anlıyoruz ve müşterileri prototiplemeden seri üretime kadar sorunsuz bir şekilde desteklemek için esnek bir üretim sistemi kurduk.

Maliyet Optimizasyonu & Risk Kontrolü

Tedarikte ölçek ekonomisinden ve olgun mühendislik uzmanlığından yararlanarak müşterilerimize şunları sunuyoruz

-

Ürün Ağacı Maliyet Analizi: Profesyonel ekip malzeme listelerini inceler ve maliyetleri düşürmek için eşdeğer alternatifler önerir

-

Erken Risk Belirleme: DFM analizi, tasarım kusurlarını önceden tespit ederek pahalı geç aşama değişikliklerini önler

-

Şeffaf Fiyatlandırma: Gizli ücret yok, piyasadaki en rekabetçi fiyatlandırma yapısını sağlıyor

Sektör Lideri Teknik Yetenekler

Topfast, teknolojik yeniliklere sürekli yatırım yapmaktadır ve fabrikamız şu ekipmanlarla donatılmıştır:

-

Yüksek Hassasiyetli Lazer Delme Ekipmanı: HDI kart gereksinimleri için mikrovia işlemeyi destekleme

-

Blind Via AOI Denetim Sistemleri: Çok katmanlı kartlarda dahili bağlantıların güvenilirliğinin sağlanması

-

Seramik Öğütme Üretim HatlarıYüksek hassasiyetli yüzey işlemi sağlama

-

Vakumlu Reçine Tıkama Makineleri: Levhanın yapısal stabilitesinin artırılması

Teknik ekibimiz, yüksek frekanslı RF devreleri, yüksek yoğunluklu ara bağlantı (HDI) kartları ve özel uygulamalar için kalın bakır güç kartları dahil olmak üzere karmaşık PCB tasarımlarını gerçekleştirebilen deneyimli mühendislerden oluşmaktadır.

Küresel Müşteriler Neden Topfast'a Güveniyor?

Bir PCB montaj ortağı seçmek sadece maliyetle ilgili değildir - ürün kalitesi ve proje başarısı ile ilgilidir.17 yıllık profesyonel deneyim, sağlam bir kalite sistemi ve müşteri öncelikli hizmet felsefesi ile Topfast, çok sayıda uluslararası marka için tercih edilen tedarikçi haline gelmiştir.

Her PCB projesinin müşterilerimizin yenilikçi vizyonlarını taşıdığını biliyoruz, bu nedenle “önce kalite” temel felsefesine bağlı kalıyoruz.Titiz süreç kontrolü ve gelişmiş teknik yöntemler sayesinde, teslim edilen her devre kartının beklentileri karşılamasını veya aşmasını sağlıyoruz. Tıbbi cihazlardan endüstriyel kontrollere, tüketici elektroniğinden otomotiv elektroniğine kadar, Topfast’ın anahtar teslimi hizmetleri, seri üretim yoluyla yüzlerce ürünü başarıyla desteklemiştir.

Güvenilir, verimli ve uygun maliyetli PCB montaj çözümleri arıyorsanız, Topfast'ın profesyonel ekibi size yardımcı olmaya hazırdır. Tasarım dosyalarınızı ve BOM'unuzu göndermekten çekinmeyin anında fiyat teklifive fikirlerinizi hızla pazara hazır ürünlere dönüştürmenize yardımcı olmamıza izin verin.