Beschreibung

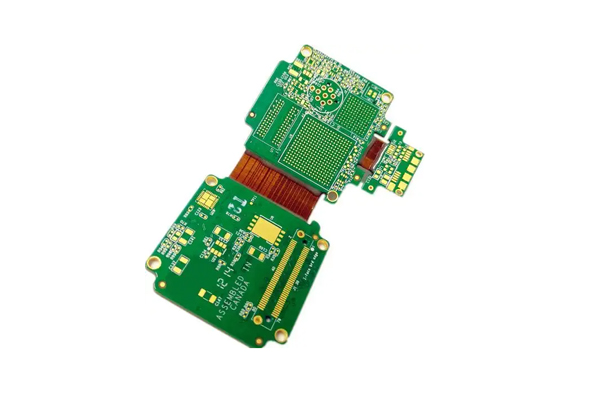

10-lagige Weich-Hart-Verbundplatten-Technologie

In der heutigen Zeit, in der elektronische Geräte mit hoher Dichte entwickelt werden, sind 10-Lagen-Starrflex-Platinen die ideale Wahl für High-End-Anwendungen geworden. Als Leiterplattenhersteller mit 17 Jahren Berufserfahrung bietet Topfast eine Komplettlösung für hochwertige Starrflex-Leiterplatten, die militärischen Standards entsprechen.

Warum sollten Sie sich für 10-lagige starrflexible Leiterplatten entscheiden?

10-lagige starr-flexible Leiterplatten zeichnen sich durch folgende Merkmale aus hervorragende Eigenschaften:

-

Ultrahohe Präzision: Mindestöffnung 0,07 mm, Mindestlinienbreite/-abstand 0,045 mm (2mil/2mil)

-

Qualität nach Militärstandard: Entspricht den IPC-Normen der Klasse 2/3, 100%ige Garantie für elektrische Prüfungen

-

Außergewöhnliche Haltbarkeit: Unterstützt 20.000 Biegetests, 3U vergoldete Oberflächenbehandlung

-

Hochspannungsfestigkeit: 1000 V Spannungsfestigkeit für anspruchsvolle Anwendungen

-

Hochwertige Materialien: Verwendung von hochwertigen Materialien wie Shengyi S1000-2M

“In der Medizintechnik und in der Luft- und Raumfahrt haben unsere 10-lagigen starr-flexiblen Leiterplatten mit einer Ausbringungsrate von 99,2 % das Vertrauen der weltweiten Kunden gewonnen.”

Kontaktieren Sie uns jetzt für die Herstellung von 10-lagigen starr-flexiblen PCBs

Starrflexible PCBs kombinieren gekonnt die Stabilität von starren Leiterplatten mit dem Flexibilität von flexiblen Schaltungen, erreicht durch:

-

Durchbruch in der Materialwissenschaft: Perfekte Kombination von starren FR4-Platten und flexiblen Polyimid (PI)-Substraten

-

Strukturelle Innovation: Komplexe Stapeldesigns mit bis zu 30 Schichten, die eine 3D-Verdrahtung ermöglichen

-

Handwerkliche Präzision: Präzise Ausrichtung und Laminierungstechnologie, die keine Blasen und keine Delaminationen zulässt

Diese Technologie ist besonders geeignet für tragbare Geräte, medizinische Instrumente, und Raumfahrtelektronik die hohe Zuverlässigkeit bei gleichzeitiger Platzersparnis erfordern.

Service aus einer Hand vom Entwurf bis zur Lieferung

Unser One-Stop-Dienste umfassen:

-

Schnelles Prototyping: Muster sind innerhalb von 24 Stunden verfügbar, um Ihre Forschung und Entwicklung zu beschleunigen.

-

Massenproduktion: Monatliche Kapazität von 50.000㎡ zur Deckung des unterschiedlichen Bedarfs

-

Strenge Qualitätskontrolle: 100%ige AOI-Prüfung + elektrische Tests zur Gewährleistung militärischer Qualität

-

Technische Unterstützung: Ein Team von Ingenieuren mit 20-jähriger Erfahrung berät Sie bei der Designoptimierung

Typische Anwendungsfälle:

-

Ein Hersteller medizinischer Geräte, der unsere 10-lagigen starr-flexiblen Leiterplatten einsetzt, konnte die Größe um 40 % reduzieren und die Zuverlässigkeit um 35 % verbessern.

-

Ein Kunde aus der Luft- und Raumfahrtindustrie konnte durch unsere Lösung das Systemgewicht um 25 % reduzieren.

Warum wählen globale Kunden Topfast?

-

Vollständige Zertifizierungen: UL, ROHS, ISO9001 zertifiziert, garantierte Qualität

-

Schnelle Reaktion: Kostenvoranschlag innerhalb von 1 Stunde, technische Rückmeldung innerhalb von 4 Stunden, 24/7-Kundendienst

-

Kostenoptimierung: Ein professionelles Team hilft, die Produktionskosten um 15%-30% zu senken

-

Globale Zustellung: Unterstützt die weltweite Logistik mit einer 99,5 %igen Liefertreue

Holen Sie sich jetzt Ihre maßgeschneiderte Lösung

Ob Sie nun 10-lagige starr-flexible Leiterplatte Muster oder Großbestellungen, Topfast kann die wettbewerbsfähigsten Lösungen anbieten.

Befristetes Angebot: Die ersten 20 Beratungskunden erhalten eine kostenlose Designprüfung und 5% Rabatt auf die erste Bestellung!

Sofortiges Angebot anfordern

Über Topfast

Topfast wurde 2008 gegründet und ist ein Anbieter von Lösungen aus einer Hand für PCB-Design, Fertigung und Montage. Zu unseren Produkten gehören HDI-Platten, dicke Kupferplatten, Hochfrequenzplatten usw., die in der Kommunikations-, Medizin- und Automobilelektronik sowie in anderen Bereichen weit verbreitet sind. Mit automatisierten Produktionslinien und strengen Qualitätskontrollsystemen sind wir bestrebt, unseren Kunden Folgendes zu bieten hohe Qualität, hohe Zuverlässigkeit elektronische Fertigungsdienstleistungen.

Unser Engagement:

✓ Qualitätssicherung auf militärischem Niveau

✓ Pünktliche Lieferung garantiert

✓ Professionelle technische Unterstützung

✓ Lösungen zur Kostenoptimierung