Products

PCB Introduction

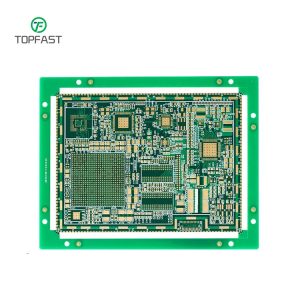

As a core element of the modern electronics industry, PCBs are used in nearly all electronic devices, serving as an indispensable medium for electrical interconnection between components.

Our Product Range

HDI Boards

High Density Interconnect technology for compact designs

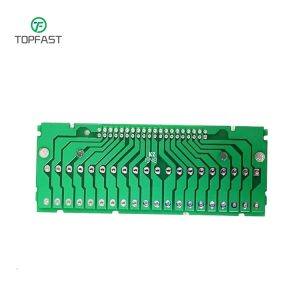

Semiconductor Test Boards

Precision boards for IC testing applications

High-Frequency Boards

Optimized for RF and microwave applications

High-Speed Boards

Designed for signal integrity in fast digital circuits

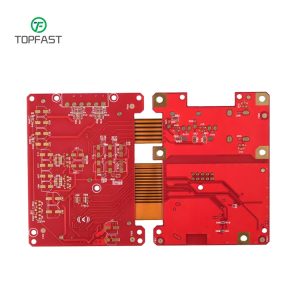

Rigid-Flex Boards

Combining rigid and flexible areas for 3D packaging

Our products are widely applied in telecommunications, medical equipment, industrial control, power supply, consumer electronics, aerospace, and automotive industries.

Core Structure of PCB

High-performance insulating composite materials providing mechanical support and electrical insulation

- FR-4, CEM-1, and CEM-3 materials

- Excellent thermal and mechanical properties

- High Tg materials for demanding applications

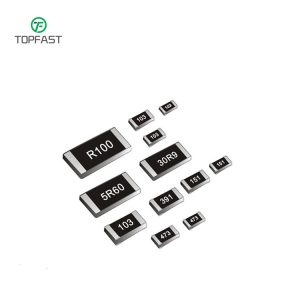

Precisely etched circuit networks for electrical connectivity

- High-purity electrolytic copper foil

- Precision etching for complex circuits

- Advanced plating technologies

Reliable component attachment and protection

- Gold-plated or tin-sprayed pads

- High-temperature solder mask

- Silkscreen for component guidance

- Surface finishes: ENIG, HASL, OSP

Our Manufacturing Capabilities

Advanced Facilities

Laser drilling machines, VCP through-hole filling lines, blind hole AOI inspection equipment, ceramic grinding lines, and vertical vacuum resin plugging machines

Expert Team

Top-tier technical team with extensive industry experience and specialized knowledge in advanced PCB technologies

Mature Processes

Comprehensive service processes from design support to final inspection ensuring reliable production

Custom Solutions

Diverse customized solutions for specialized requirements including high-layer count, high-frequency, and high-reliability boards

Application Fields

Consumer Electronics

Wearables, mobile devices, smart home products requiring compact, high-density designs

Industrial Equipment

Automated control systems, robotics, and machinery needing robust, reliable PCBs

Communication

5G base stations, networking equipment, and telecom infrastructure requiring high-frequency performance

Defense & Aerospace

Radar systems, avionics, satellites demanding high-reliability and ruggedized boards

Automotive

ADAS systems, infotainment, and vehicle control units requiring automotive-grade reliability

Medical Equipment

Diagnostic devices, imaging systems, and patient monitoring needing high-precision boards

Quality Commitment

Inspection

Inspection

Testing

Testing

Analysis

Analysis

Improvement

Improvement

We implement rigorous quality control measures throughout our manufacturing process:

- Incoming material inspection and certification

- In-process quality checks at every production stage

- Automated optical inspection (AOI) for defect detection

- Electrical testing and functional verification

- Final inspection and quality assurance documentation

Our quality management system ensures consistent performance and reliability for all our PCB products.

Ready to Start Your PCB Project?

Get a Free Quote NowPCB Assembly FAQ

Find answers to common questions about our PCB manufacturing and assembly services

TopFast provides high quality, on-time delivery of PCBs, PCBAs and one-stop solutions, integrating design, manufacturing, assembly, and sourcing in one global specialized supplier.

- We constantly introduce new equipment and technology.

- We use high quality materials to ensure the quality of boards.

- We have more than 25 experienced executives and technicians who have been engaged in PCB production for more than twenty years, with rich experience in production management and professional PCB skills. Because we have an efficient direct sales channel, our overhead is extremely low. Every penny you pay is for the highest quality!

The fastest lead time we can support is 12 hours. 1 hour prompt quote. 4 hours prompt engineering. This depends on your product requirements and quantity. In addition, lead time will be included in your quote.

For small packages, we recommend using an express courier (e.g. DHL, UPS, FedEx and EMS door-to-door service!). This is the fastest but also the most expensive way. For large parcels, ocean freight is the best solution. We can only give you accurate shipping rates if we know the quantity, weight and shipping method details.

Yes. We can lay out the PCB according to your schematic and then arrange the production. Please contact us at Please send your schematic and requirements to op@topfastpcb.com and we will provide a quotation accordingly.

Online: Get a free quote on our website. Send an e-mail to: op@topfastpcb.com with an email containing the following information: name, company, address, phone number, email address, product number, quantity, product time and any other information you would like to share with us. Attach your gerber file.

As a global PCB manufacturer, our factories are located in Guangzhou, China and Shenzhen, China, utilizing the advantages of each region to provide you with the best service.

We do not offer free PCBs, if you want to verify our quality before mass production, it is better to submit a prototype order. After verifying our quality, you can easily place an order for any quantity you need.

Sure. You can place a prototype order first. Use any of the options to check the quality and then let us know if you want to proceed with mass production.