Description

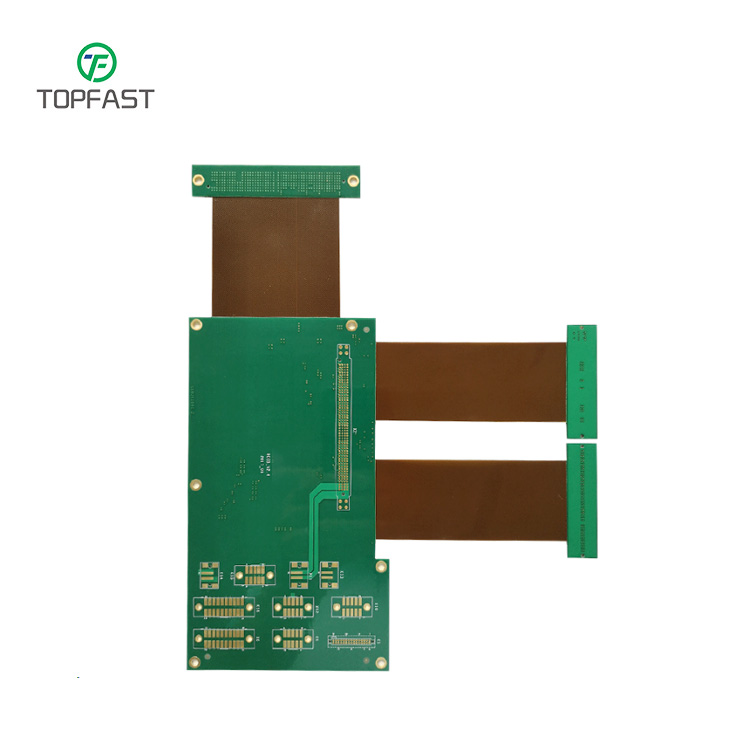

The four-layer rigid-flex PCB is a circuit board design that combines the characteristics of rigid and flexible circuit boards for flexibility and high reliability. It usually consists of a four-layer structure, including a top layer, a bottom layer, a power layer, and a ground layer, and is suitable for complex electronic devices that need to meet both signal transmission and power requirements.

It consists of the following four core functional layers

Top Layer (Component Layer): Used for mounting and soldering electronic components;

Inner layer 1 (signal layer): mainly carries high-speed signal alignment;

Inner layer 2 (power supply layer): dedicated to power distribution and power supply network;

Bottom layer (signal/soldering layer): both signal alignment and soldering functions.

Core advantages of four-layer boards

High-density wiring: reduces board area and improves space utilization.

Signal integrity: optimizes high-frequency signal transmission and reduces interference.

Mechanical Flexibility: Accommodate bending and folding requirements.

Cost Effectiveness: Reduces overall manufacturing costs in complex designs.

Compared to traditional single and double-sided boards, four-layer PCBs offer three significant advantages:

Space utilization is increased by more than 40%, allowing for higher-density circuit designs.

60% lower power impedance and 50% lower noise interference through specialized power layer design;

For high-speed circuit design above 100MHz, signal integrity is significantly improved.

Key Considerations for Rigid-Flex PCB Designs

1. Optimize Functional Partitioning

High-frequency signal processing modules are concentrated in the rigid section to ensure signal integrity

Flexible interconnect area provides 3D spatial adaptation with ±15° dynamic bending capability

Typical applications: wearable device joints, robotic joints

2. Advanced Materials and Processes

Flexible substrate: Liquid Crystal Polymer (LCP), εr=2.9@10GHz

Key process:

Laser microvia drilling (≤50μm diameter)

Embedded capacitor integration (3x higher density)

3D printed conductive traces (30/30μm line width/spacing)

3. Multi-physics field simulation

Electromagnetic simulation: HFSS full wave analysis (0.01dB accuracy)

Mechanical simulation: ANSYS bending fatigue test (>100k cycles)

Thermal simulation: Flotherm CFD analysis (±2℃ gradient control)

4. Modular System Architecture

|

Parameter

|

Conventional Design

|

Rigid-Flex Design

|

|

Volume

|

100% (Baseline)

|

60-70%

|

|

Reliability

|

1x

|

3-5x improvement

|

|

Revision Cycle

|

4-6 weeks

|

1-2 weeks

|

Core Components

Rigid area: processor/memory (high-density components)

Flexible Area: Daisy Chain Topology Interconnects

Certification and Validation

40% weight reduction

80% reduction in failure rate in vibration environments

Mandatory: ≥3 simulation iterations + JIS C5016 compliance

Application Scenarios

Double-sided flexible circuit boards are used in a variety of applications where flexibility and reliability are required, including but not limited to:

Consumer Electronics: Flexible connectors in devices such as smartphones and tablets.

Automotive Electronics: Double-sided flexible circuit boards provide improved flex and vibration resistance in a variety of sensors and controllers within automobiles.

Industrial Controls: In automation equipment and robotics, double-sided flexible circuit boards can accommodate complex mechanical movements and space constraints.

Why choose us?

We have specialized in the PCB field for more than 20 years and have an ISO9001 quality management system certification, RoHS, ISO14001 environmental management system certification, TS16949 automotive quality management system certification, and other certifications.

TOPFAST is a professional PCB supplier. We are committed to providing the highest quality rigid-flex PCB boards at the most competitive prices. Our platform has the best reputation on Google. We have advanced equipment and a professional technical team to ensure on-time delivery of quality products.

For Rigid-Flex PCBs, we specialize in:

A multilayer rigid-flex PCB board, also known as a double-sided rigid-flex PCB board, is a combination of a flexible board and a rigid board, a type of circuit board in which a thin layer of flexible material is combined with a rigid backing layer, which is then pressed together into a single component.