Description

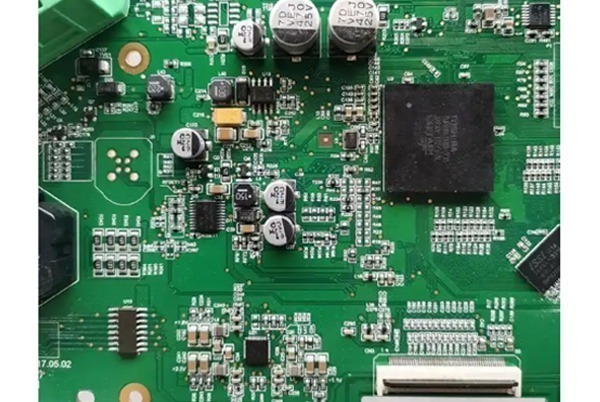

With 17 years of deep expertise in the PCB industry, Topfast understands the unique challenges of automotive electronics PCBA manufacturing. From engine ECUs to autonomous driving systems, we provide highly reliable circuit solutions for global automotive brands, ensuring your automotive electronics designs are worry-free.

Why Do Global Automakers Choose Topfast?

17 Years of Automotive-Grade Manufacturing Experience: Since our founding in 2008, we’ve supplied PCBA services to automotive brands, including Mitsubishi, and have produced over 2 million square meters of automotive-grade circuit boards. Last year, one of our clients’ infotainment system PCBA achieved a zero PPM (parts per million) defect rate.

True One-Stop Automotive Electronics Solution

Design Consultation: A Technical team with 20+ years of experience helps avoid design pitfalls

Material Selection: Only use AEC-Q200 compliant automotive-grade materials

Precision Manufacturing: ±25μm circuit control precision

Rigorous Testing: 100% compliance with IPC-6012DA Class 3 standards

Our Automotive Electronics Manufacturing Advantages

1. Production Lines Specifically Designed for Automotive Electronics

In our 20,000 sqm modern facility, we’ve equipped:

Laser Drilling Machines: For microvia processing in automotive HDI boards (minimum 50μm)

Vacuum Resin Plugging Machines: Ensures the reliability of thick copper boards under thermal shock

3D AOI+AXI Inspection Combo: Detects 99.99% of soldering defects

Monthly Capacity:

100,000㎡ PCB (including high-frequency, thick copper, and other specialty boards)

60 million SMT solder joints (YAMAHA high-speed placement machines with ±15μm accuracy)

2. Quality Standards Exceeding Industry Requirements

Beyond meeting ISO 9001 and IATF 16949, we’ve established a unique “Triple Assurance System for Automotive Electronics”:

1. Incoming Material Control: Direct partnerships with TI, NXP, and other OEMs to avoid counterfeit risks

2. Process Control: 38 critical control points with real-time monitoring

3. Final Testing: Including -40℃~125℃ thermal cycling, mechanical vibration, and other real-world vehicle environment simulations

3. Solving Special Challenges in Automotive Electronics

We provide expert solutions for your key concerns:

Thermal Management: Through simulation-optimized layout, reduced temperature by 22℃ for one client’s ECU module

Signal Integrity: Impedance control tolerance ±7% (better than industry ±10% standard)

Long-Term Reliability: Conformal coating process passes 1000-hour salt spray test

Automotive Electronics Success Stories

Case 1: EV BMS System

Challenge: 6-layer thick copper board (3oz) + complex heat dissipation requirements

Solution: Thermal vias + embedded copper block technology

Result: Zero failures after 3 years in mass production

Case 2: Autonomous Driving Domain Controller

Challenge: 20-layer HDI board + 0.3mm BGA pitch

Solution: Laser drilling + stepped impedance design

Result: Yield increased to 99.2%

How We Guarantee “High Quality + Fast Delivery”

1. Vertical Integration: Full in-house control from PCB production to SMT assembly

2. Smart Warehouse System: Ample stock of common automotive-grade components

3. Rapid Response System:

1-hour quotation

Fastest 3-day sample delivery

24/7 customer support

Our clients include quality-demanding companies like DJI and Hikvision, who choose Topfast for one simple reason let professionals handle professional work.

Exclusive Automotive Electronics Service Packages

Flexible options for different needs:

Quick-Turn Service: 3-5 day delivery (ideal for R&D verification)

Mass Production Service: Million-unit capacity (supports JIT delivery)

Full-Turnkey Service: Complete solution from design→PCB→SMT→testing

Special Offers for New Inquiries

Free DFM analysis

5% discount on first order

Dedicated account manager throughout the project

The Topfast team consists of over 1,000 professionals, including 30% senior technical staff. We understand the extreme safety requirements of automotive electronics, which is why we adhere to the philosophy that “quality isn’t inspected in, it’s built in.”

Contact our automotive electronics expert tam anytime – let our 17 years of specialized experience safeguard your project!

Get Your Custom Quote Now