Description

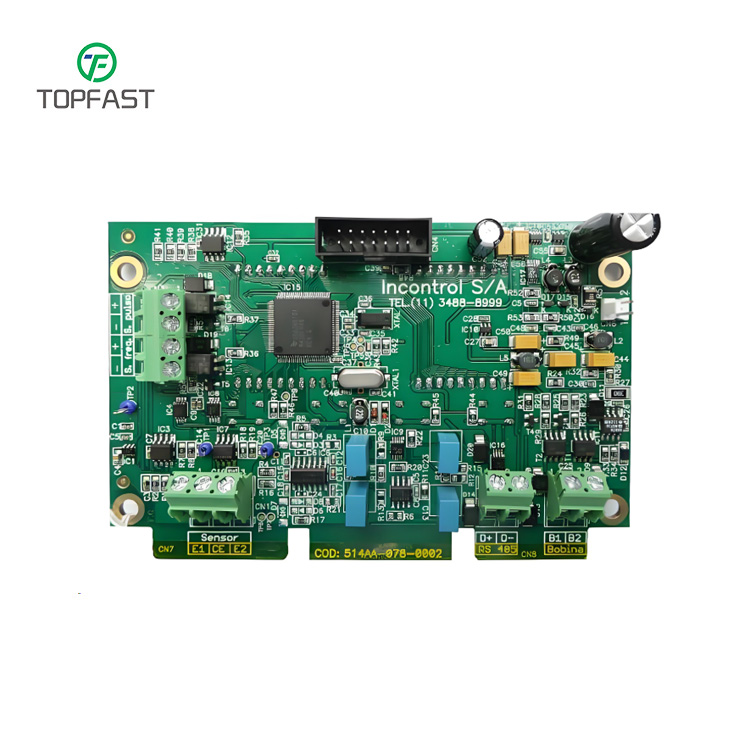

PCBA is to solder electronic components to the PCB to realize the function of the board and product performance. This process includes several links: component procurement, PCB production, SMT (surface mount technology) chip processing, DIP (dual in-line package) plug-in processing, PCBA testing, and finished product assembly etc.

|

|

| Item |

Capability |

| Advantages |

—-Professional Surface-mounting and Through-hole soldering technology |

| —-Various sizes like 1206,0805,0603 components SMT technology |

| —-ICT(In Circuit Test),FCT(Functional Circuit Test) |

| —-PCB Assembly With UL,CE,FCC,Rohs Approval |

| —-Nitrogen gas reflow soldering technology for SMT. |

| —-High Standard SMT&Solder Assembly Line |

| —High density interconnected board placement technology capacity. |

| Components |

Passive Down to 0201 size |

| BGA and VFBGA |

| Leadless Chip Carriers/CSP |

| Double-sided SMT Assembly |

| Fine Pitch to 0.8mils |

| BGA Repair and Reball |

| Part Removal and Replacement |

| Quantity |

Prototype & Low Volume PCB Assembly, |

| from 1 Board to 250, or up to 1000 |

| and pcba customized |

| Type of assembly |

SMT,Through-hole |

| Solder type |

Water soluble solder paste,Leaded and Lead-Free |

| Bare Board Size |

Smallest:0.25*0.25 inches |

| Largest:20*20 inches |

| File Formate |

Gerber files, Pick-N-Place file, Bill of Materials |

| Type of Service |

Turnkey,partial turn-key or consignment |

| Component Packaging |

Cut Tape,Tube,Reels,Loose Parts |

| Turn Time |

Same day service to 15 days Service. |

| Testing |

Flying Probe Test,X-ray inspection AOI Test. |

| PCB Assembly Process |

Drilling—-Exposure |

Advantages of our PCBA processing

Flexible adjustments according to customer needs, to meet personalized needs, and rapid response to market changes.

Adopt automated equipment such as a counter, wave soldering machine, etc., to improve production efficiency and precision and reduce labor cost.

Real-time monitoring of product quality through advanced technologies such as AOI (Automatic Optical Inspection) and X-ray inspection to ensure the yield rate.

High-quality PCB assembly: 4-layer PCB assembly, sprayed with triple-proof paint, with good resistance to high and low temperatures.

High-efficiency PCB assembly: using an advanced high-speed SMT machine. The assembly can be completed in one day at the earliest.

LED PCB assembly 2 layers LED PCB assembly, using high-quality IC solder. Perfect clean SMT.

High Precision PCB Assembly: PCB assembly accuracy is up to +/-50um. The maximum accuracy is ±30um.

Why choose us?

1. One-stop PCB PCBA Service

We can help you with a one-stop service. To support you with the whole process from function research and development, product design discussion, PCB manufacturing, component procurement, to PCB assembly.

2. Advanced Equipment

There are more than 385 equipment, mainly imported from Germany, Japanand Taiwan. Such as LDl automatic exposure machine, automatic plating line, laser drilling machine, automatic testing machine, automatic V-cutting machineand other advanced equipment.

3. Advanced Technology

There are more than 28 employees of our R&D team, including 2 doctoral students and 8 master’s students. We can do 3 3-step HDI PCBs with 0.4mm pitch holes. The technology is in the leading position in the industry.

4. Superior Service

7*24-hour online service! We have a professional service team to follow the whole process for key customers and key orders. Also, we have a professional account manager for each customer to meet customer various demands.